Squeezable tubes line

Squeezable tubes line Colibri-1001 + BA100 "L" tubes

The squeezable tubes line refurbished by Rinova is a line for the packaging of squeezable tubes capable of producing up to 50/60 cartons per minute.

The line is composed as follows:

Tonazzi Colibri-1001: an automatic tube filler suitable to fill and close aluminium, polyethylene and laminated tubes.

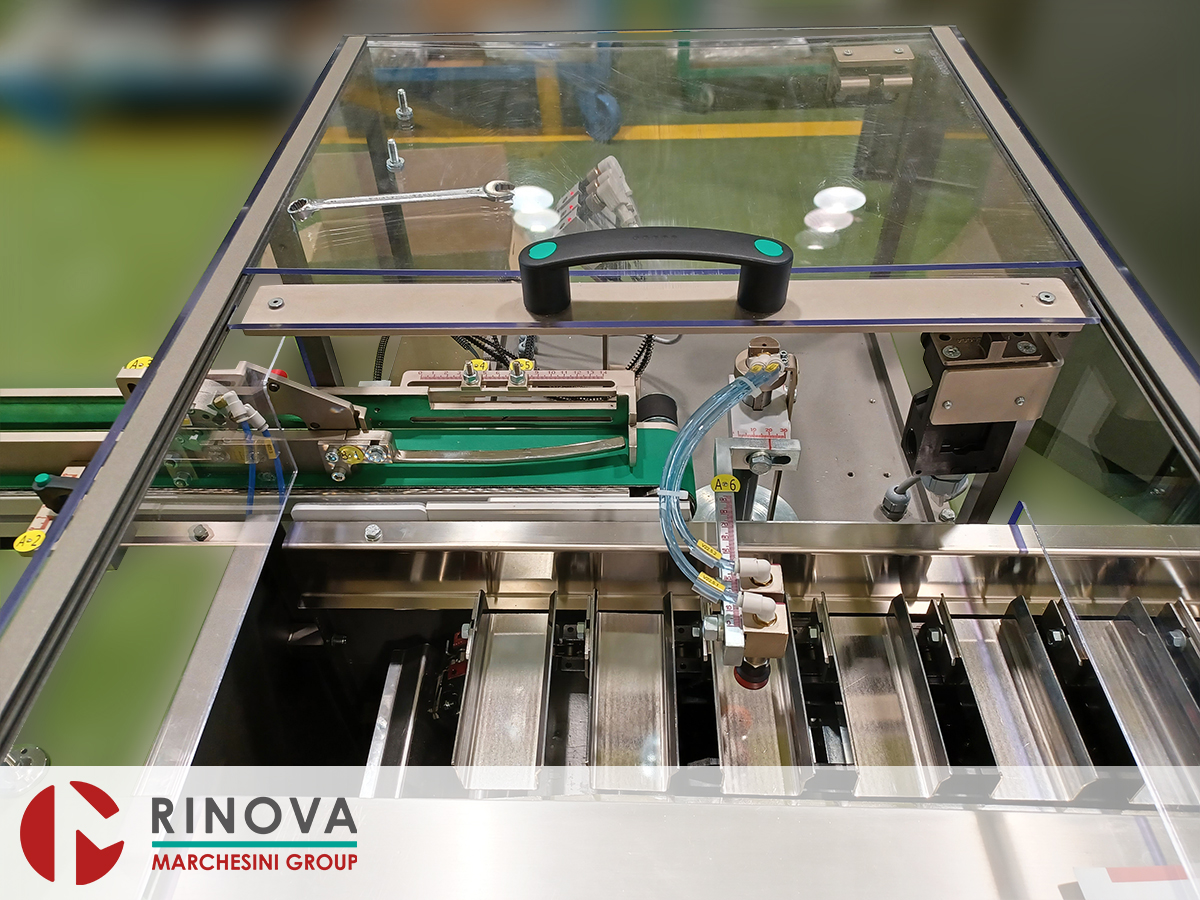

Marchesini BA100 “L”: a horizontal intermittent-motion cartoner for squeezable tubes, specifically designed to address the main cartoning applications for medium production rates.

Tonazzi Colibri-1001

Main features

- AISI 304 stainless steel machine body and bottom covers

- AISI 304 stainless steel removable covers to easily reach inside parts

- Electronic speed variator with digital setting of machine speed

- Safety coupling to protect mechanical members

- Parallel index drive similar to Ferguson

- Anticorrosion treated upper parts

- Electronic control and safety systems controlled by a Programmable Logic Control (PLC S7-300 SIEMENS)

- SIEMENS “TP700” interactive display of machine functions and alarms provided with on-line help to solve minor problems; advanced control of adjustments, such as:

- Machine speed

- Product tail cut-off

- Counter

- Storage of operation parameters to form a collection of recipes of the different products filled on the machine

- 12-position turntable with twin tube holders

- AISI 316L stainless steel infeed hopper, 40-liter capacity

- Automatic high capacity tube feeder, Mod “JUMBO”

- Control of the presence of tubes having a wrong position on tube loading chute (capsized tubes)

- Device to pneumatically hold tubes during transfer into tube holders

- Pusher assembly ensuring tubes are properly positioned in relevant tube holders and consequently perfectly closed

- Automatic tubes registration assembly with photocell and potentiometer to delay tubes stop in its correct position

- AISI 316 L stainless steel volumetric dosing group with Tri-Clover connections

- Mechanically operated dose adjustment enabling variations without machine stops

- fixed injector with pneumatically operated nozzle-closing valve cutting product tail off and avoiding product leaks

- Tubes bottom-up fill device lifting tubes holder during filling phase with an adjustable and progressive stroke of approx 135 mm

- Device to stop the dosage if the tubes are missing (no-tube – no-fill)

- One filling nozzle

- One dosing piston

- Control of non-ejected filled tubes stopping machine and enabling to remove a non-ejected ones

- Device to stop tubes loading enabling to discharge tubes present on turntable before any planned machine stop

- Safety guards in methacrylate with micro switches

Marchesini BA100 “L”

Software, mechanical and electronic parts have been completely refurbished. The machine is sold with the user manual and the technical change over datasheet, CE certified and complies with the existing safety standards.

The BA 100 is equipped with a bucket feeding chain into which, by means of dedicated feeders, are placed the products to be cartoned. Operation is completely automatic. One sensor checks for the presence of the product in the bucket and calls the correspondent carton and leaflet (if necessary), enabling the sensors of correct retrieval.

Carton erection is carried out by the traditional blade opening system, which guaranties optimal operation with the widest range of cartons and cardboard quality. Change over is simple and fast, assisted by millimetric scales.

The Siemens operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages The speed is set from the control panel and allows for adjustment to the optimal production speed.

Standard control and safety devices:

- Minimum carton and leaflet detectors;

- Leaflet presence checking device;

- Control of correct carton erection;

- Pusher’s safety device;

- Mechanical overload on the main motor;

- Operator’s interface;

- Safety guards according to CE standards, with Schmersal micro switches.

Technical data

Filling accuracy

- ± 1% for non-aerated products

- The actual filling accuracy depends on the product characteristics and the volume to be dosed

Maximum mechanical speed

- up to 80 Tubes/Minute

- The machine output depends on the tube capacity and diameter, tube wall thickness, quality and color of the plastic material and on the type of product to be handled

Dosage

- From 3 to 44 ml

Tubes diameter

- From 10 to 25 mm max

Tubes height with cap

- From 50 to 140 mm

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]