MST 200

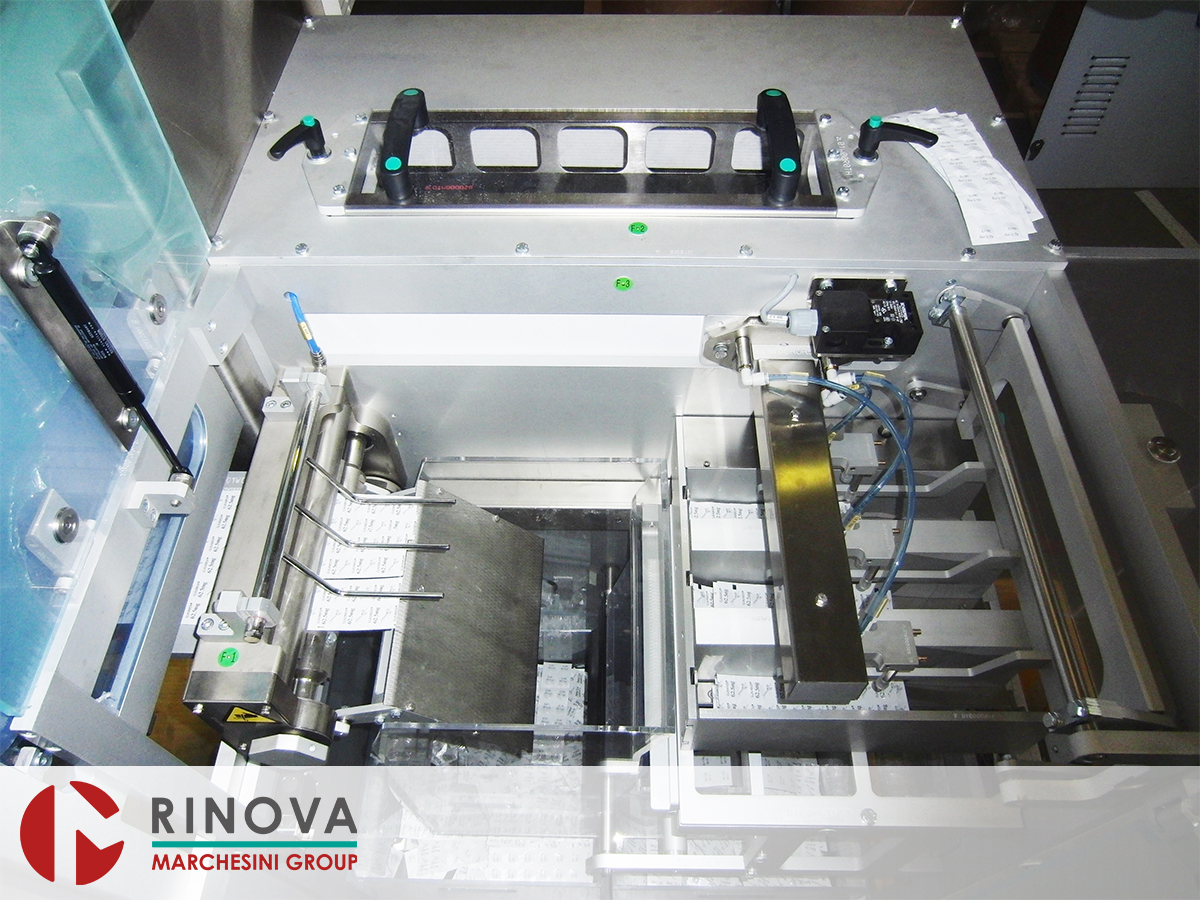

MST 200 Automatic strip packaging machine

The Marchesini MST 200 is suitable to pack solid products, like tablets and/or dragées, caplets, capsules and effervescent etc. in sealed Strips. The machine fills the strip with product, seals and discharges it at the machine outfeed.

The mechanical parts have been completely refurbished, while the electronic parts and software are newly designed and built. The machine is sold with a new certification CE, complies with current safety standards, accompanied by all the dedicated manuals and customized format change cards.

The MST 200 is available in a standalone version or can be connected to cartoning machines.

This machine has been designed to minimize the layout, so that the operator supervises the entire production process.

Main Features

- The main machine structure is made in Stainless Steel AISI304S, with some parts in Nickel-plated Steel and Anodized Aluminium;

- Balcony-type construction with separate motorization from the functional modules, to ensure a high level of cleanliness;

- Possibility to process different kinds of thermo-sealable films;

- The machine can be in standalone version or connected to the cartoner (in line or 90 degrees);

- The machine housing is completely sealed in order to avoid inlet of the product inside of its body and the operation zone is completely balcony-type;

- Machine surfaces are built without embedding and sharp edges. Surfaces are easily cleanable;

- All the assembling slots are closed. Most of the assembling screws are made from the inside of the machine housing;

- The machine has been designed and manufactured in accordance with cGMP norms and it is delivered with CE marking.

Product Feeding

Product Pre-Feeder, complete with:

- Hopper in Stainless Steel AISI316L capacity 30 liters approx;

- Vibrating lane support in Stainless Steel AISI316L with support to fit sorting riddle;

- Linear vibrating base;

- Product contacts parts are AISI 316L & Hard Anodized Anticorodal Aluminium, FDA Approved;

- All the feeding parts may be easily disassembled by means of quick knobs (Tool-Free).

Technical and Functional Specifications

- Two-reel holders equipped with the end control sensors;

- Film unwinding unit;

- Sealing rolls supporting unit;

- Web deviation roll 90 degrees;

- Film dragging unit with clutch and longitudinal film cut;

Transversal cut with Servo motor with selection of cuts from 1 to multiples of 1; - Ejection unit of empty or incomplete Strips: in case there is an incomplete or empty Strip then all the aligned Strips on the same row are sent towards the rejects collection box;

- In case of standalone machine version, packed Strip collection must be provided by Customer;

- The machine dimensions are reduced to the minimum and the maximum height is 1670 mm from floor (excluding hopper that is however provided with inspection window to verify the product charge by the operator).

Formats

- All size change-over operations can be performed by the line operator;

- Change-Over parts are designed to minimise the use of tools;

- All adjustments are clearly indicated with references to rulers;

- All parts and units to be substituted are clearly identified;

- All references (labels) are clearly visible.

Technical data

Nr. of channels

- Min 4 - Max 8

Mechanical speed

- (RPM) 100 Horizontal Cuts per minute

Production speed

- It has to be calculated considering number of possible feeding channels, product dimensions and based on the quality of thermo sealing materials to be used

- The speed always depends on product feeding possibilities, automatic product feeders used, applied solutions for product pusher and on the types of mounted additional accessories

Reel dimensions

- External Max 400 mm

- Internal 70 mm - 75 mm

- Width Max 200 mm

Quality of Strip materials

- Strip sealing is made by coupling two thermo-sealable films suitable to be sealed continuously at high production speeds and having a low melting point to preserve product from heat

- The thermo-sealed film must have a thickness/resistance capable to allow sealing with constant pressure

- It will be possible to evaluate and to classify the quality of thermo-sealable Materials, (Paper, aluminum and Multi-Layer), and its machinability only based on internal tests during preparation & machine setting-up. The quality of material used, in direct mode affects the production speed

- In strip technical drawings there are two types of thermo sealable materials (one for paper and one for aluminum) which are suggested by Marchesini to maximize the potential of the machine and get a good performance

- The thermo sealable materials provided by the customer for trials have to be always accompanied by a proper technical data sheet issued by the material manufacturer. Furthermore, the thermo-sealable films must have an external treatment for “over printing” thus allowing the ink to adhere to the foil. Without this surface treatment the printing of foil is not guaranteed

IMPORTANT

- 1670 mm (hopper excluded)

Pneumatic components

- SMC

Noise level

- Not exceeding 80 dB(A)

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and ΠCertificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]