MC 820

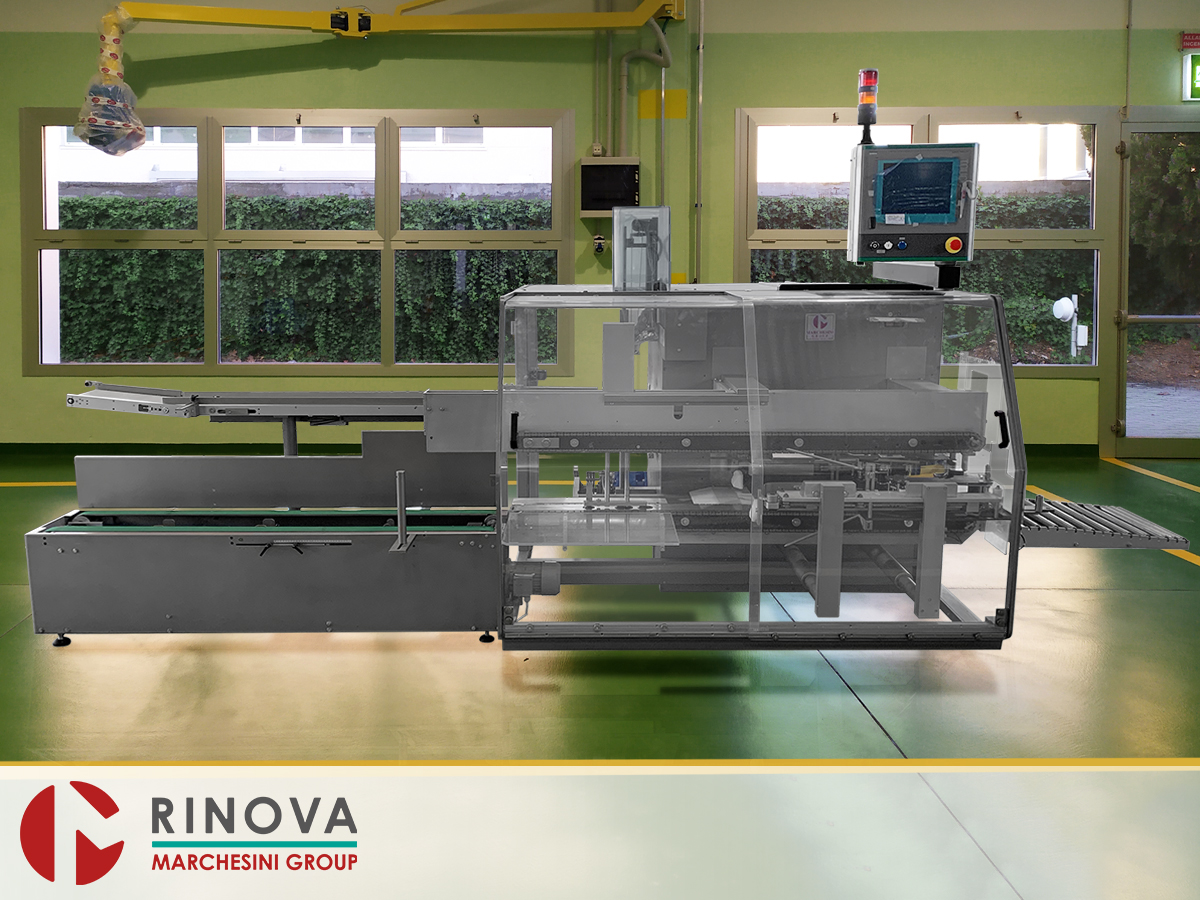

MC 820 Automatic case-packer

The Marchesini MC820 is an automatic machine for collation and insertion of single and collated cartons into the case. Case closing with not overlapping adhesive tape.

Main Features

- Balcony design to improve accessibility, maintenance and cleaning operations;

- Machine composed of three working sections: cartons collation, case feeding and closing;

- Working area and case transport, separated from the mechanics placed on the rear;

- Case changeover adjustments in “B” (width) and “H” (height) quotes, are made through servo motors with direct command from the operator panel;

- “A” quote (length) automatically managed when setting of the format parameters is made from the PC.

Cartons Collation

- Collation of cartons, coming from the upstream machine, on the infeed conveyor belt;

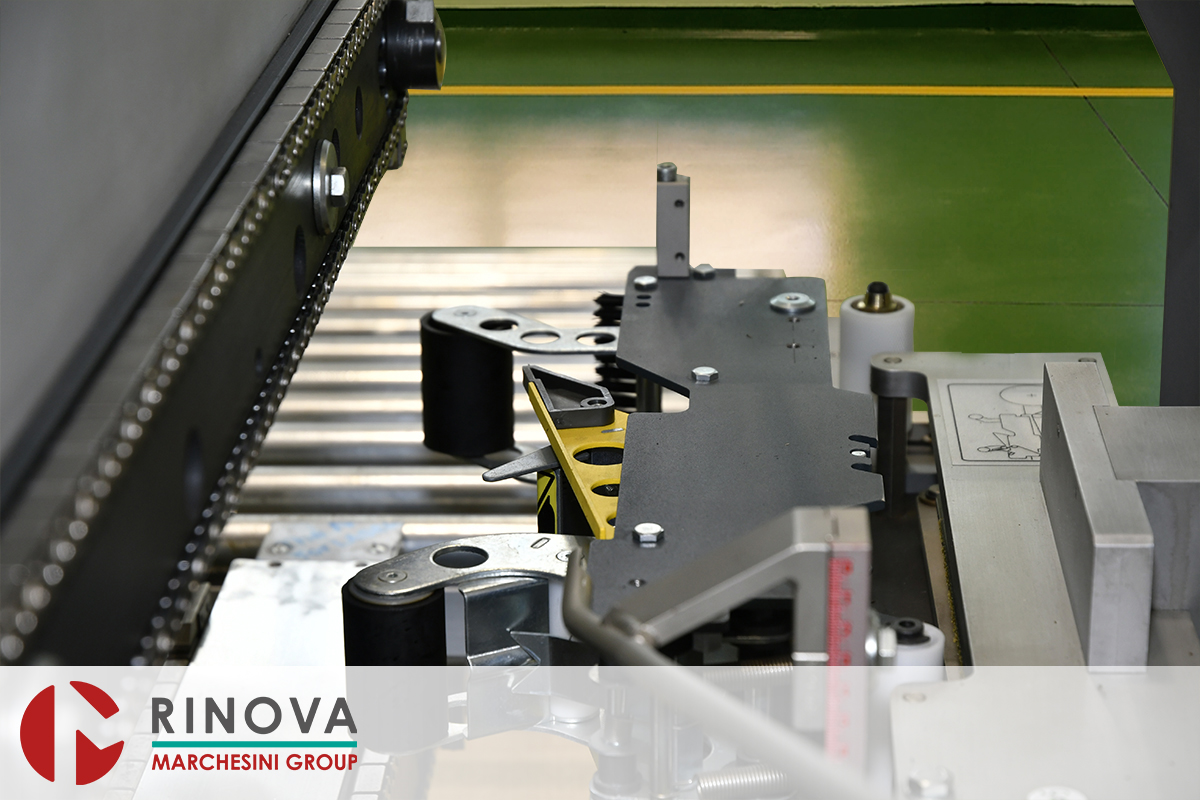

- Pick & Place for the direct transfer of the cartons into the hopper, with vertical stacking from the bottom to the top;

- Product pick up detected at each cycle of the collation, to assure that the defined number of products has been collated;

- Machine stop in case of wrong pick up;

- Product transfer into the case, at the end of the collation phase, by the mechanical command of pusher and hopper.

Cases Feeding

- Case feeding on a 1750 mm (68.897”) long conveyor belt, placed at 450 mm (17.716”) from the floor, accepting many stacks of flat cases all over its length and one stack in the pick-up area;

- Suction cups arm for the picking of the flat case from the top of the stack and case transfer into the forming and loading station; case forming and keeping in the opened position during the introduction of product;

- Possibility to process a wide range of cardboard boxes sizes without the use of change parts;

- Automatic adjustment of the strokes of the picking arm and case transport chains, without neither manual settings nor size parts.

Cases Closing

- Flaps folding and subsequent case closing with adhesive tape.

Safeties and Controls

- Safeties guards in methacrylate, integrated in the machine frame;

- Emergency circuits and protections with safety level;

- Overload control on the machine brushless motorizations;

- Torque control on product loading hopper and pusher;

- Minimum load control, with machine under idle status in case of lack of cartons at the infeed;

- Maximum load control on the infeed conveyor with stop of the upstream machine upon receipt of a signal detecting maximum load of product;

- Minimum load control of the cases inside the magazine with acoustic pre-warning signal and machine stop;

- Control for the unsuccessful case opening with machine stop;

- Control for the adhesive tape breaking with machine stop and acoustic signal in case of tape reel end.

Technical data

Carton sizes

- A: Min 20 mm - Max 160 mm

- B: Min 10 mm - Max 150 mm

- H: Min 50 mm - Max 260 mm

Collation

- A1: Min 130 - Max 510 mm

- B1: Min 110 - Max 335 mm

- H1: Min 110 - Max 335 mm

Case sizes

- A: Min 140 - Max 520 mm

- B: Min 120 - Max 350 mm

- H: Min 120 - Max 350 mm

Mechanical speed

- Max. 10 cases/minute

Standard voltage

- 400 Volts, 3-phase, Neutral & Ground, Frequency 50 Cycles

Electrical cabinet

- On board, it can be opened from the rear side of the machine

Electric functions and Touch Screen control panel. Commanded by one Industrial Siemens PC, autotest included, complete with:

- Start, stop, reset and emergency push buttons

- Jog connector

- Display to visualize notifications for the operator as well as necessary size management selections

- Password protected services access

- Message presentation including services and Help menu

- Production data: total and partial hours counter, good products counter, speed indicator

- Complying with EMC norms (El. Magnetic Compatibility)

- Two additional foreign languages can be added to Italian language

Pneumatic components

- SMC

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]