PS 510

PS 510 Automatic case-packer

The Marchesini PS510 is an automatic machine suitable to receive single or bundled products on infeed conveyor, collate and introduce them into a case taken from magazine, tape close the case with non overlapping self adhesive tape and discharge the sealed case.

Main Features

- The basic machine is complete in all following parts and delivered with the CE mark;

- Structure in finished and painted aluminium panels. Covers in Methacrylate. Machine safety guards with electric interlocks;

- Carton infeed conveyor 1400mm (55”) long with speed adjustment;

- Pneumatic product elevation assembly;

- Infeed guides for cartons on the elevation section, adjustable by handwheel;

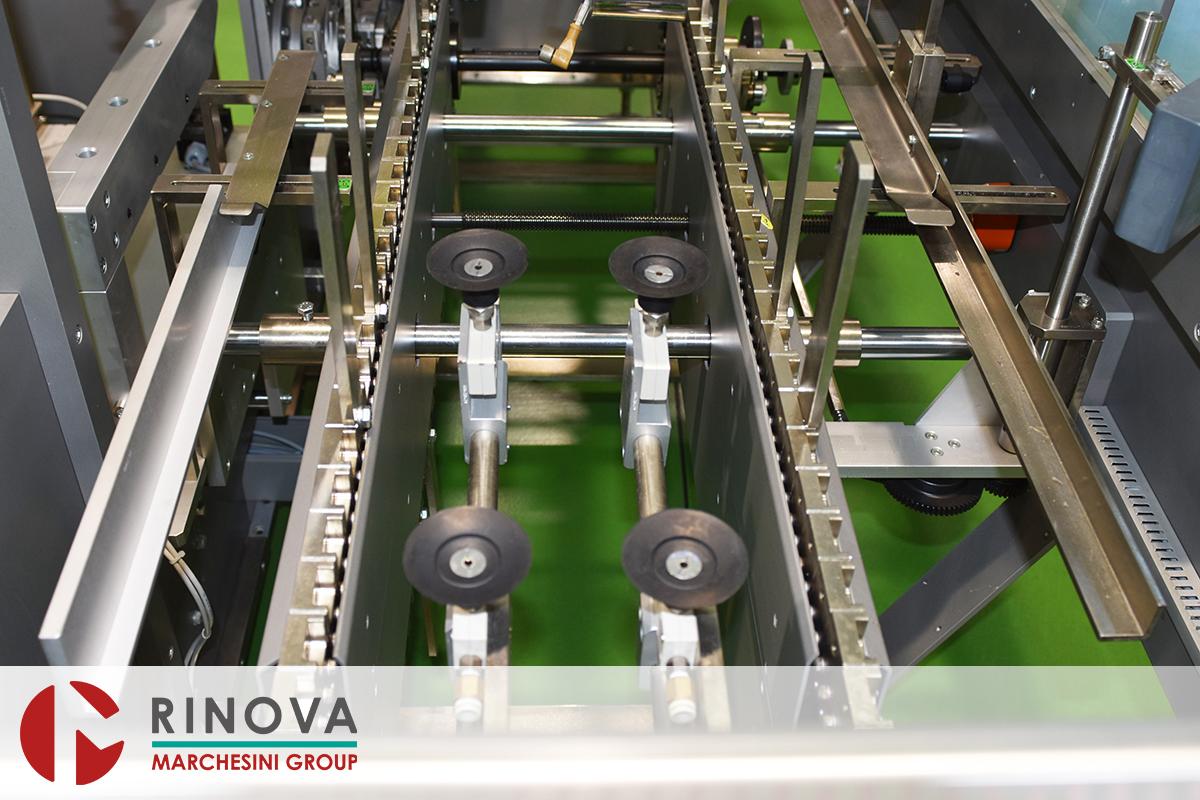

- Product collation hopper in stainless steel AISI 304S;

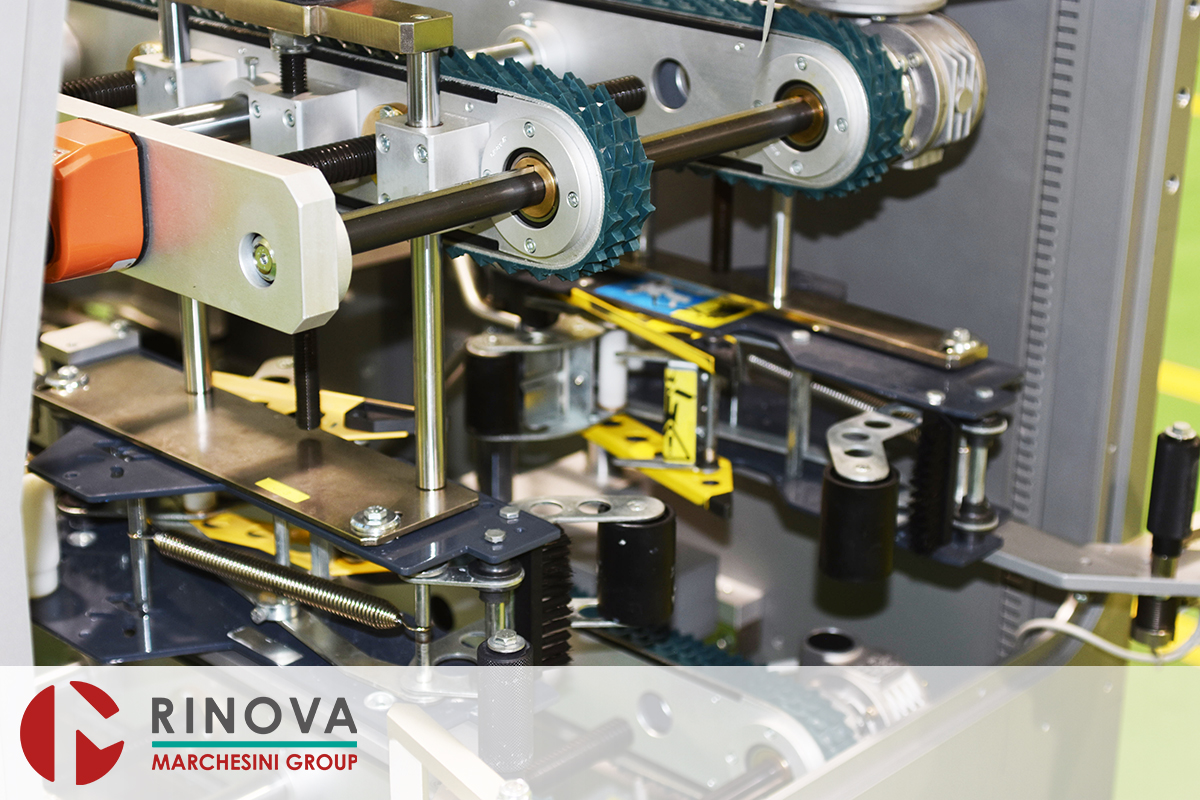

- Carton pusher unit driven by a gear-motor with speed continuous adjusting;

- Inclined magazine for folded cases;

- Motorized case pick-up arm with suction cups;

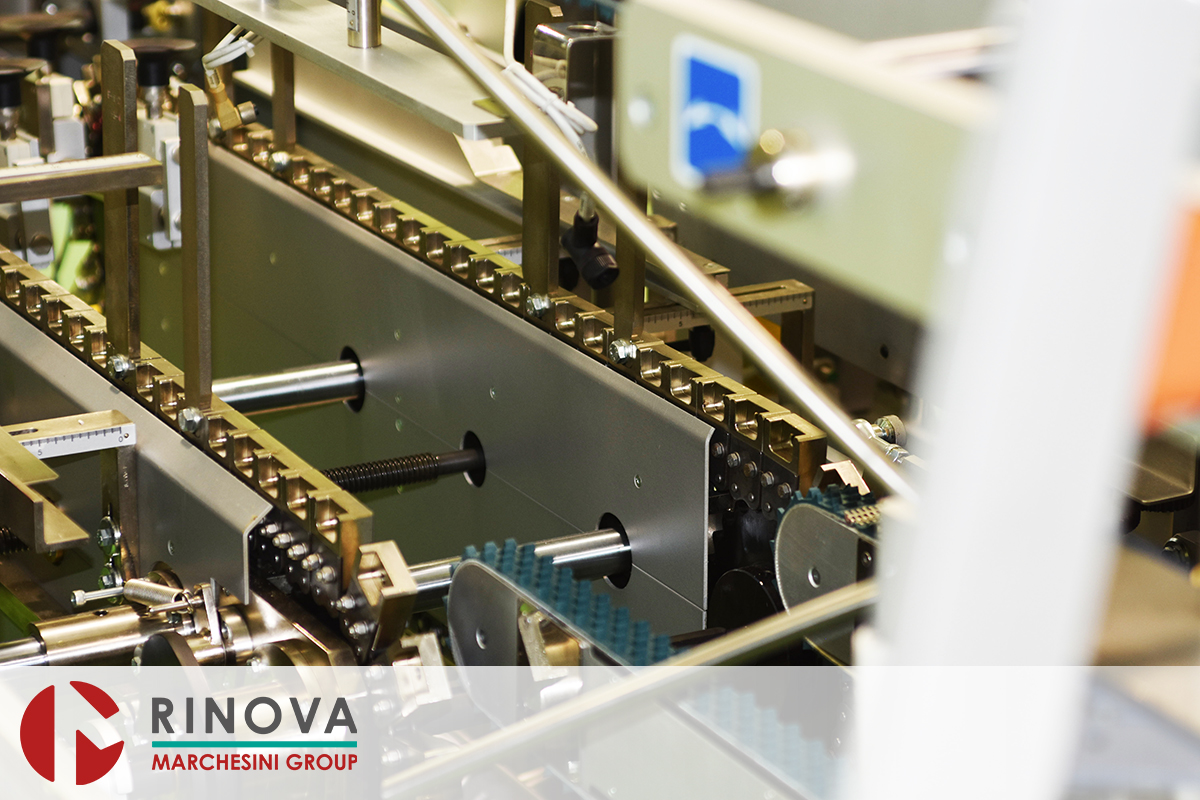

- Adjustable case transport chain;

- Front side case flap folders. Rear side case flap folders driven by servo motors;

- Upper and lower case transport belts;

- Two self-adhesive taping units for not overlapping finish.

Functional Features

- The Casepacker PS-510 accepts a wide size range;

- Cartons presented in infeed at height of approx. 860-930mm (33,86”- 36,61”) are conveyed downwards through an inclined conveyor to a height of approx. 500 mm (19.5”), where they pass onto the vertical collation unit;

- On the collation unit, if required, depending on the size range, a pre-collation station can be foreseen. This allows recovering the time needed to transfer the cartons into the hopper or into the case;

- A motorized arm with suction cups picks the flat case, squares it and inserts it between the lugs of the transport chain. With the next sequence the case is transferred to the loading position;

- Once the number of collations is achieved, the pusher shifts them into the hopper up to the penultimate layering;

- During the introduction of the last stratification, once the pusher is arrived at the “layering point”, the mobile hopper starts to move at the same speed of the pusher and penetrates the carton thus assuring the total product introduction;

- After loading, the case is transferred to the two discharge belts;

- During transport, case closure and taping is achieved;

- At the same time the carton which was waiting is transferred to the loading station repeating hereafter the above described phases.

Cases can be sealed as follows:

- Standard: non-overlapping self-adhesive tape, included in the basic machine

- Optional: overlapping self-adhesive tape, or

- Optional: Hot-melt closure with a NORDSON® unit.

Machine complete with:

- All parts equipped to handle one size product in infeed;

- One collating pattern and one case size;

- Suitable for non overlapping self adhesive tape sealing.

Technical data

Product sizes

- A: Min 20 mm - Max 250 mm (0,787” – 9,842”)

- B: Min 16 mm - Max 150 mm (0,629” – 5,905”)

- H: Min 55 mm - Max 180 mm (2,165” – 7,086”)

Collation range

- A1: Min 130 mm - Max 440 mm (5,118” – 17,323”)

- B1: Min 110 mm - Max 340 mm (4,33" – 13,385”)

- H1: Min 110 mm - Max 340 mm (4,33" – 13,385”)

Case sizes

- A length Min 140 mm - Max 450 mm (5,511” – 17,716”)

- B width Min 120 mm - Max 350 mm (4,724” – 13,779”)

- H height (depth) Min 120 mm - Max 350 mm (4,724” – 13,779”)

Infeed height

- Min 860 mm - Max 930 (33,86” –36,61”)

Discharge height

- Min 730 mm - Max 830 mm (28.74” ÷ 32,68”)

Mechanical speed

- Up to 10 Cases/Minute

- Up to 17 Cases/Minute (if the machine is equipped with the option “Double Stroke Case Transport”)

Standard voltage

- 400 Volts, 3-phase, Neutral & Ground. Frequency: 50 Cycles

Electrical system

- The machine complies with international CE standards and is tested according certified Quality Plan

Electric cabinet

- Placed on the rear side of the machine, opens completely for easy accessibility

Three colours advisory lights (5 functions)

Electric functions

- Commanded by an Industrial Siemens PC. Autotest included

PC Control Panel, complete with

- Start, stop, reset and emergency push buttons

- Jog connector

- Password protected services access

- Touch screen display to visualize advisory messages to the operator as well as necessary size management selections

- Function and machine status information

- Production data: partial hours counter with reset, total hours counter, good products counter, speed indicator

- Message presentation including services and Help menu

- Two additional foreign languages can be added to Italian language

- Conforming to EMC norms (El. Magnetic Compatibility)

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]