MA 50

MA 50 Intermittent motion cartoner for stick pack

The Marchesini MA 50 is an intermittent motion automatic machine with horizontal transport of the carton, suitable for packing products into three-flaps straight or reverse tuck-in cartons. Watch the MA 50 for stick pack in action.

Main Features

- Design, manufacturing and ergonomics, in accordance with GMP norms;

- Versatility and efficiency in a small footprint;

- Balcony design to improve accessibility, maintenance and cleaning operations;

- Cartons transport and closing movements running in oil bath, enclosed in two drive boxes;

- Working zone on operator side, separated from the rear of the machine;

- Main drive consisting of 2 servo motors (one for the machine and one for the conveyor drive), both operating synchronized through electric axe;

- Cartons transport system with adjustment (“a” carton quote) from a single point of intervention, through handwheel and digital indicators;

- Adjustment of carton length (“h” dimension), by widening the belt transport system, through handwheel and digital indicators;

- Separated removable bins for collecting rejected products, cartons and leaflets;

- Easy and quick size changeover through digital indicators and millimeter scales.

- CE marking.

Product Feeding

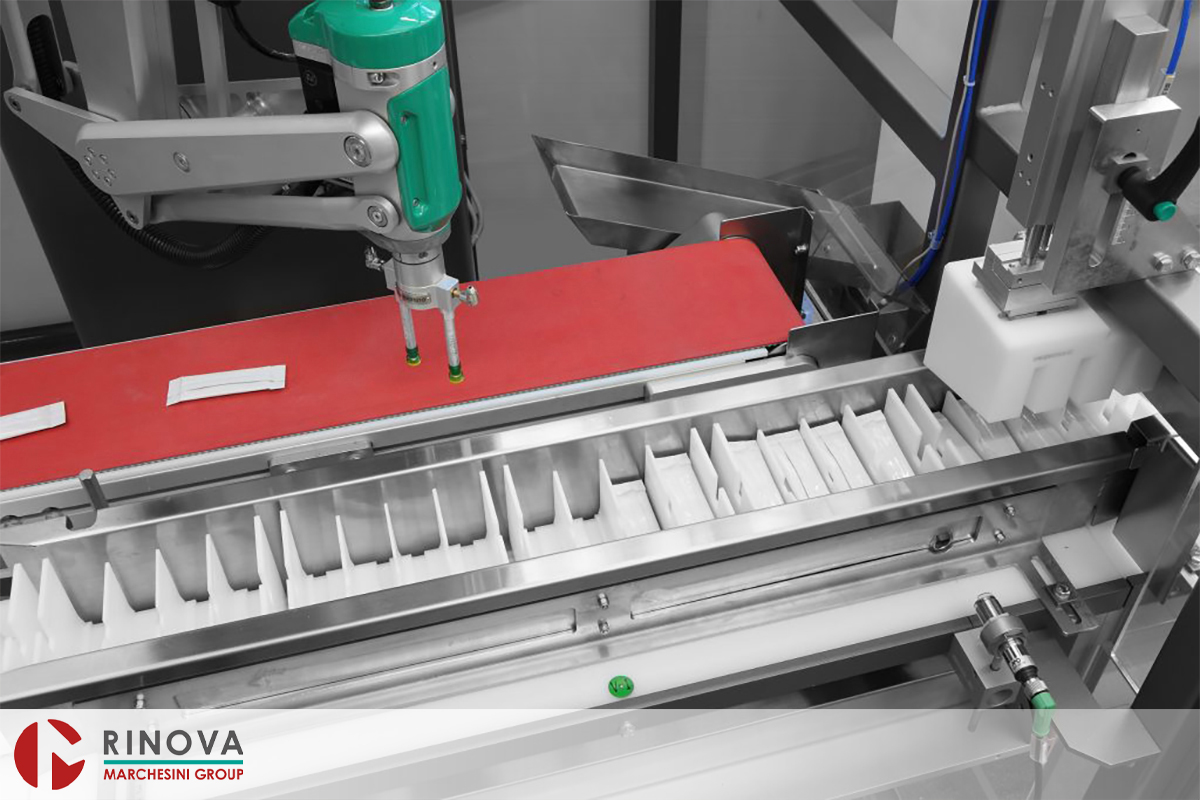

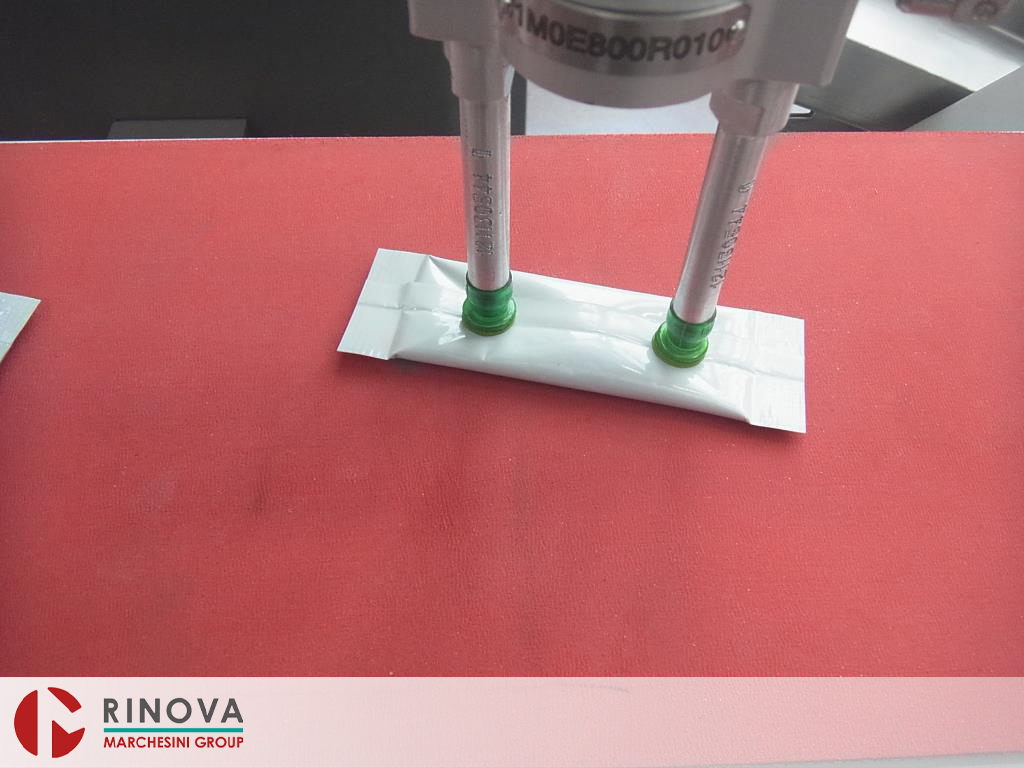

- The stick packs are fed by loading in bulk onto a belt where a dedicated camera recognizes the position of the product. Then, a robot picks the stick packs up and positions in the transport belt with plug-in buckets in order to facilitate the change over activities.

Cartoning Section

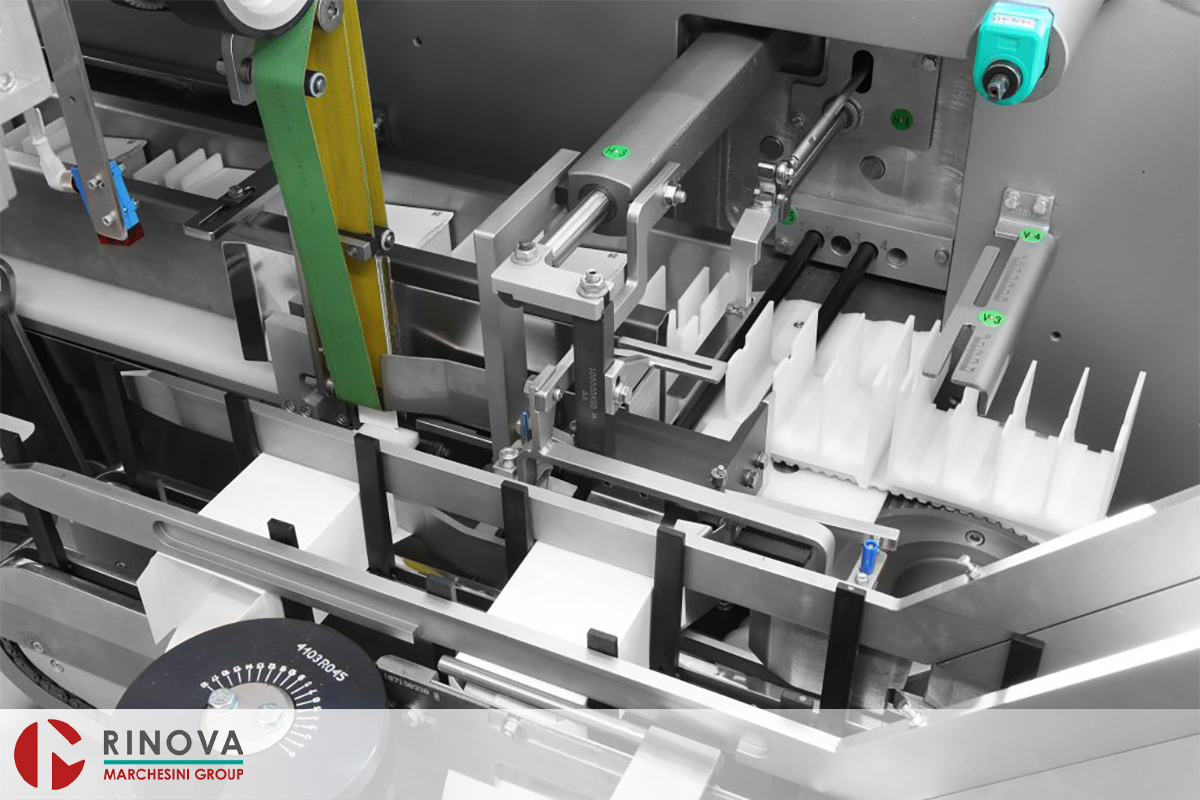

- Cartons magazine with motorized pusher belts having a standard length of 750 mm (29,52”) with minimum load control. The magazine is placed in a lower than the product transport chain and it is close to the operator in order to improve the cartons loading which is made at about 900 mm. Simplified adjustment of magazine guides and pickup by means of millimetre scales;

- Cartons opening system, consisting of an oscillating arm with suction cups and mechanical 90 degrees pre-breaking action, with direct transfer of the squared open carton into the belt transport system. Positive carton pickup control from magazine;

- After the opening, carton is transported by a parallel mounted lug chain, which maintains the carton perfectly squared;

- The carton transport system is adjustable from an only point and it is equipped with digital indicators;

- The widening of the belt transport system is made through hand wheel and digital indicators for the adjustment of carton length (“h” dimension);

- Product, arriving from the infeed chain, is inserted into the carton by a pusher placed opposite the operator side;

- After the closing phase, lateral belts transfer the carton to the machine outfeed.

Installed Safeties

- Safety guard in methacrylate transparent material, integrated on the machine frame, with safety micro switches on all the opening parts with machine stop in emergency mode and release of the air pressure;

- Overload control on the main motor with mechanical torque limiter and immediate machine stop;

- Overload safety on product pusher and machine stop. After clearance, a reset is mandatory;

- Machine stop after three consecutive errors;

- No product, No carton, No leaflet (if group is present).

Machine complete with:

- Product bucket infeed chain with adjustable buckets (related to product width);

- Handwheel, digital indicators and millimetre scales for easy size change;

- Machine complete in all parts and equipped to handle one size product and carton.

Technical data

Formats range (The indicated data are for reference only. They are subject to be modified whenever manufacturing needs dictate so)

- A: Min 40 mm (1,57”) - Max 165 mm (6,50”), pitch 203.5 mm (8,00”)

- B: Min 20 mm - Max 100 mm (0,79” - 3,94”)

- H: Min 80 mm - Max 200 mm (3,15” - 7,87”)

- The size range is referred to the carton size

Maximum mechanical speed

- up to 50 cartons/minute

- The production speed is always dependent on the possibility of feeding and characteristics of the product as well as on the configuration of the product, as well as on the accessories added to the standard machine

Prefolded leaflets

Booklet magazine

Standard voltage

- 400 Volts, 3-phase, Neutral & Ground. Frequency: 50 Cycles

Electrical system

- The machine complies with international CE standards and it is tested according to the certified Quality Plan

Three colours advisory lights (5 functions)

Electric components

- A standard components list is available on request

Electric functions

- Commanded by an Industrial Siemens PC. Autotest included

PC Control Panel, complete with

- Start, stop, reset and emergency push buttons

- Jog connector

- Password protected services access

- Touch screen display to visualize advisory messages to the operator as well as necessary size management selections

- Function and machine status information

- Production data: partial hours counter with reset, total hours counter, good products counter, speed indicator

- Message presentation including services and Help menu

- Two additional foreign languages can be added to Italian language

- Conforming to EMC norms (El. Magnetic Compatibility)

Power input

- 1.5 kW, standard version with tuck-in closure

Air consumption

- 20 Nl/min. at 6 bar

Pneumatic components

- SMC

Noise level

- Not exceeding 80 dB(A)

Technical documentation

- Original standard CE Instructions Manual (one hardcopy + one CD Rom) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]