F 40

F 40 Multipack stretch banding machine

The product coming from one single row, is grouped into the requested pattern and banded with polyethylene band.

Main Characteristics

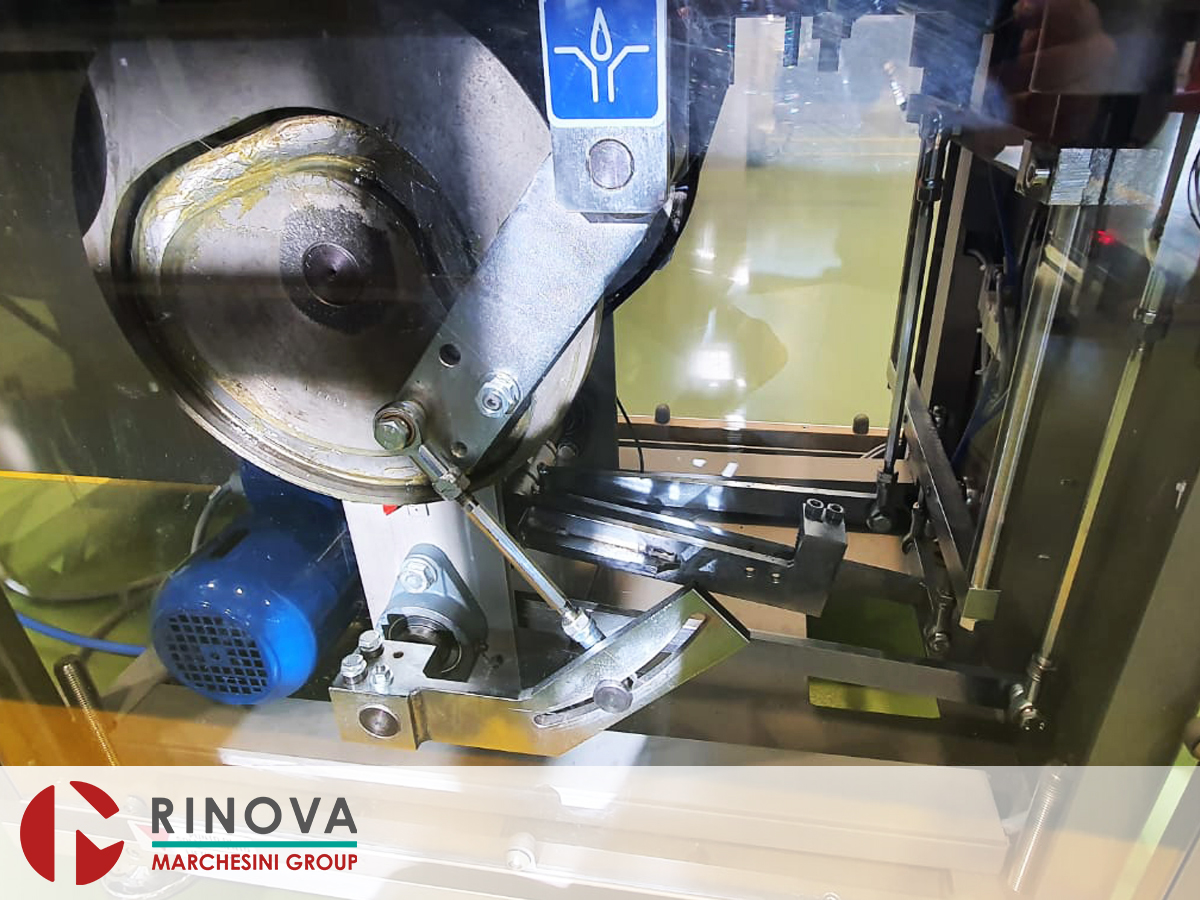

- Automatic intermittent motion machine, with mechanical movements;

- Security clutch and cam controls;

- All the movements are controlled by security devices: in case of overloading the machine will stop and the cause will be signalized on Display;

- Reduced dimensions and solid frame. Base in sealed and painted carpentry with motor drive;

- In the machine design, GMP norms have been followed to meet the pharmaceutical packaging requirements, allowing an easy access for maintenance, cleaning and size changeover purposes;

- The machine can be supplied in symmetric version, in-line or 90 degrees feedings.

Banding and Sealing Section

- The product is introduced against the film by a pusher driven by cams, defining the bundle wrapping;

- A peculiar feature of the sealer clamping device allows a high quality seal in terms of stretching resistance, as well as surface result;

- Bundle is kept in an orderly manner during sealing operations;

- Sealer temperature is constantly checked by thermo-regulators;

- A suitable sealer cooling system allows working even at a very high speed.

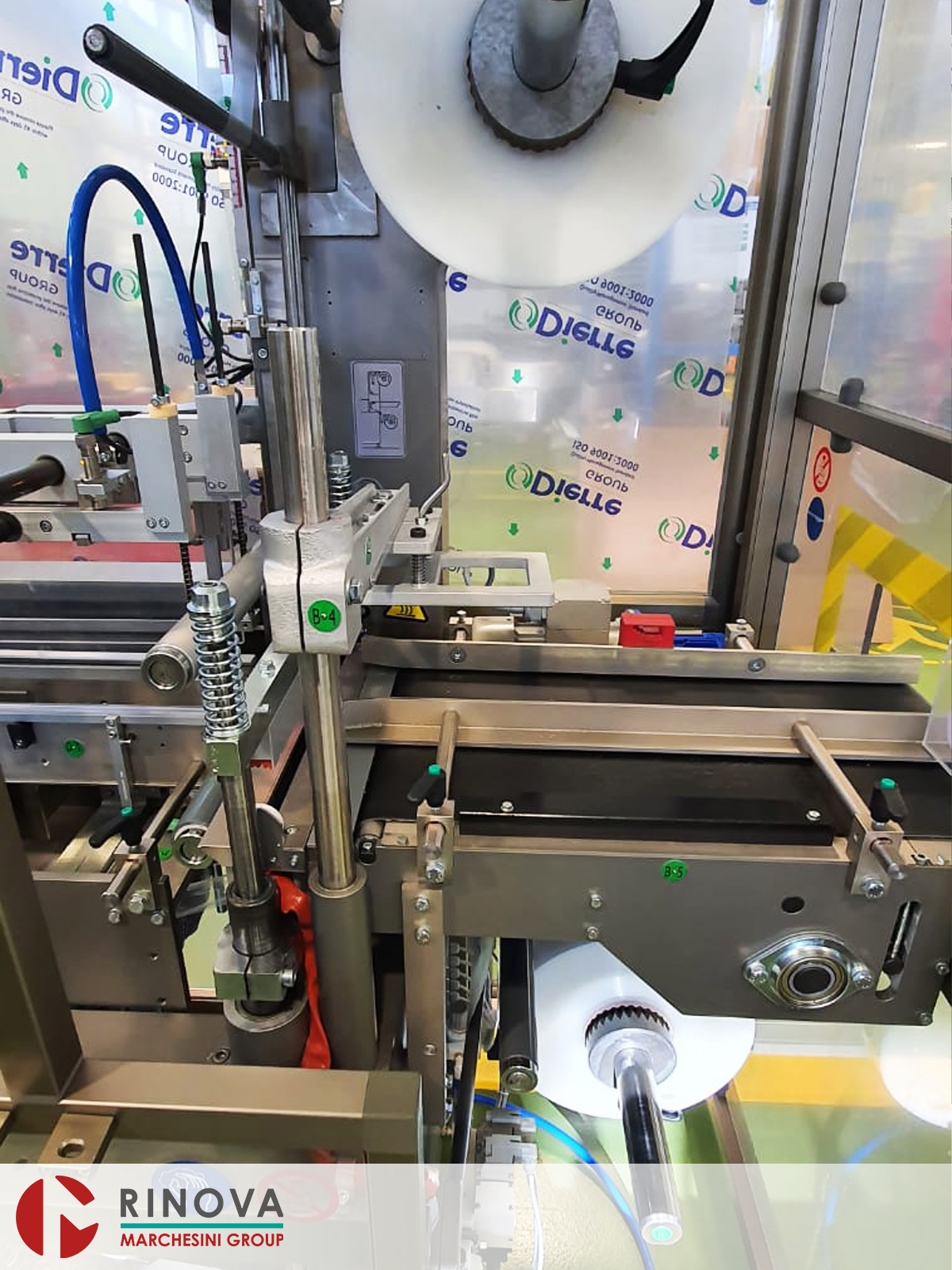

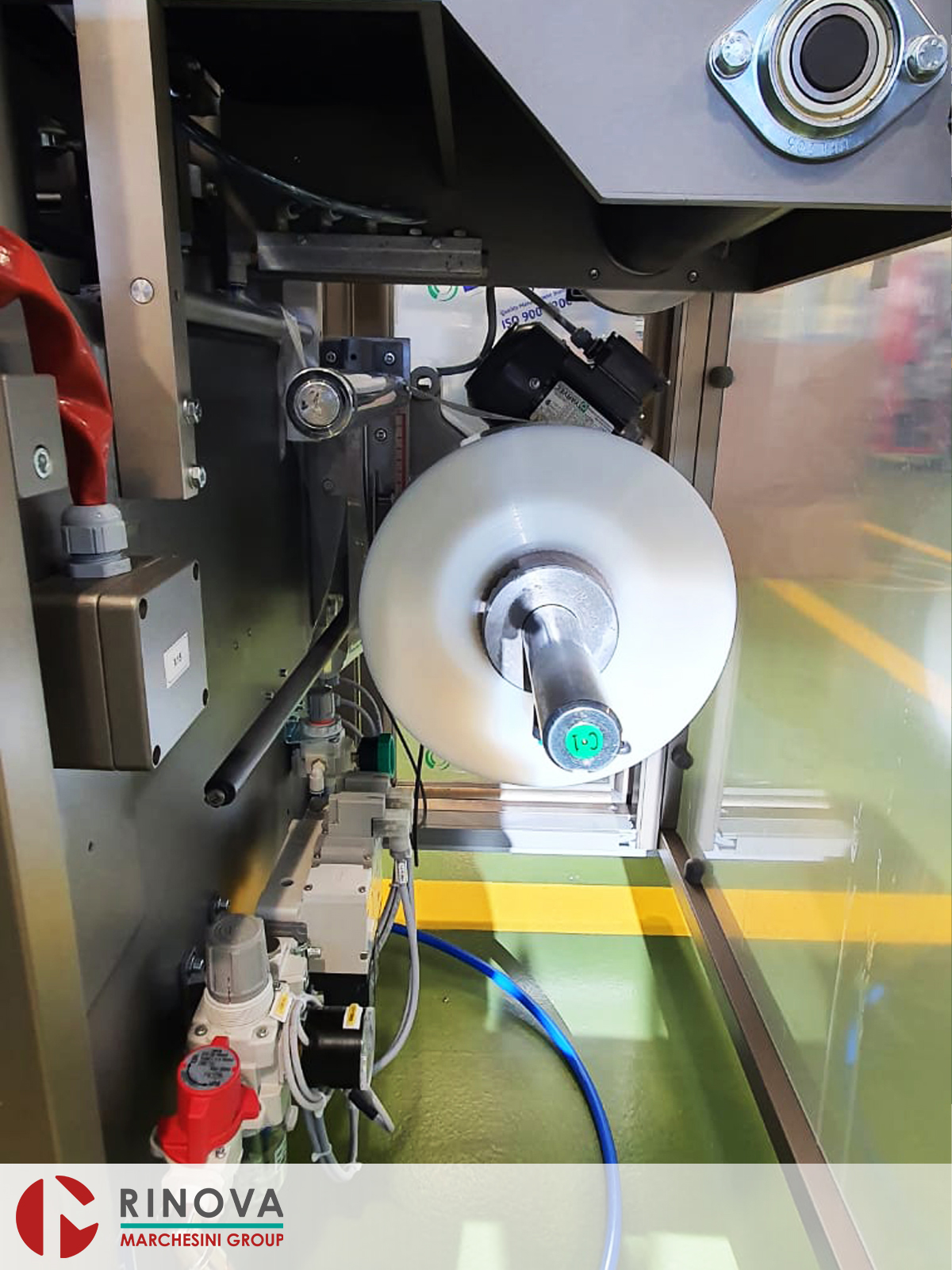

Reel Holder Section

- The wrapping film will be unwinded by two motorized reels;

- Adjustable film stretching around the bundle;

- In case of film breaking, the machine will stop in emergency with proper signal on Display;

- Two sensors indicates the reel ending.

Controls

- Different sensors allow to know the status of the main machine parts, such as product missing;

- Speed adjustment during changeover size.

Installed Safeties

- Total safety guard, in Methacrylate, integrated in the machine frame. Microswitches on all the open doors, with machine stop in emergency and compressed air discharge;

- Main movements are protected and controlled by proximity with indication on control panel and machine stop upon emergency conditions. On restore performed, a reset will be necessary and the machine will return automatically in the normal working position.

Machine complete with:

- Easy size change over through hand wheel with digital indicators and millimetric scales;

- One set of size parts suitable to collate and wrap one type of product.

Technical data

Product size data

- The indicated data are for reference only. They are subject to be modified whenever manufacturing needs dictate so. Machine versions with different size range are available as optional

- A: Min 30 mm - Max 350 mm

- B: Min 12 mm Max 200 mm

- H: Min 50 mm - Max 300 mm

Bundle size data

- A: Min 30 mm - Max 350 mm

- B: Min 25 mm - Max 200 mm

- H: Min 12 mm - Max 300 mm

Reel Dimensions

- Core diam. 75 mm, O.D. max. 300 mm. Width Min 40 mm - Max 300 mm

Maximum mechanical speed

- up to 40 bundles per minute

- The output always depends on bundles collation requested

Infeed & Outfeed Height

- Product Infeed Height: 850 ± 40 mm

- Outfeed Height: 850 ± 40 mm + Elevation height

Electric Cabinet

- Placed on the rear side of the feeding, with door, opens completely for easy accessibility. Display placed inside the electrical cabinet on operator side

Standard Voltage

- 400 Volts, 3-phase, Neutral & Ground. Frequency: 50 Cycles

Three colours advisory lights (5 functions)

Machine Functions

- Controlled by SIEMENS PLC “S7-300”, including Autotest

Command Panel: SIEMENS "TP700", Touch Panel, backlit 5,7" blue mode display. Touch for finger- pens and glove operation

- Complete with start, stop, reset and emergency push buttons

- Jog connector

- Password protected services access

- Display to visualize advisory messages to the operator

- Function and machine status information

- Production data: total hors, partial hours (with reset) and machine speed

- Other displays depending on mounted accessories

- Message presentation including services and Help menu

- All displays are in Italian and it is possible to add other two languages

- Conforming to EMC norms (Electro Magnetic Compatibility) therefore No disturbance to other surrounding electronic equipment

Installed Power

- 2 kW, standard version without shrink-tunnel

Air Consumption

- 50 – 100 Nl/min. at 6 Bar

Pneumatics

- SMC Components

Noise Level

- Not exceeding 80 dB(A)

Technical Documentation

- Original standard CE Instructions Manual (one hardcopy + one CD Rom) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]