Blister Line

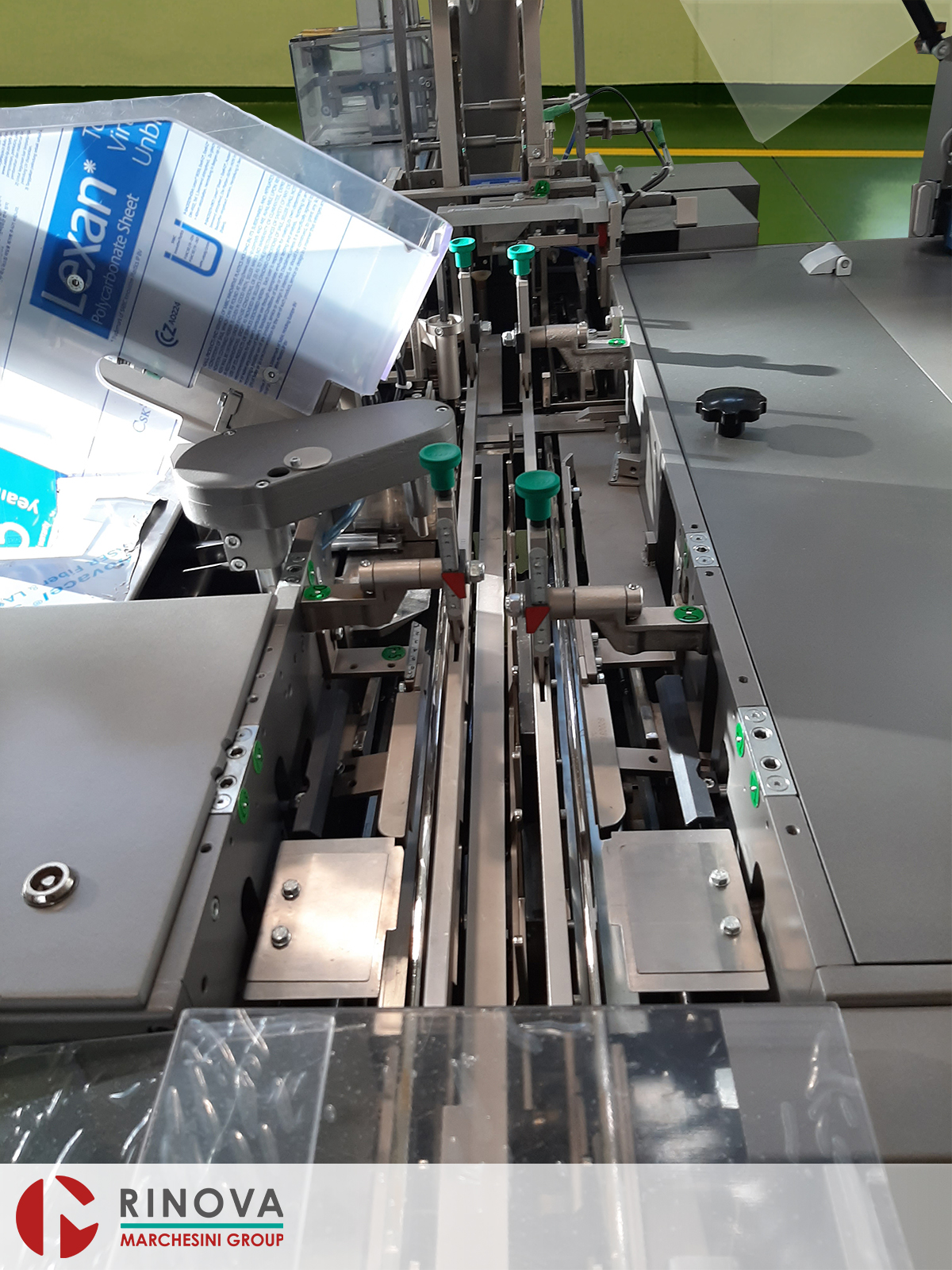

Blister Line MB421 + BA100 blister

The Blister Line refurbished by RINOVA is a line for blister packaging which can produce up to 80 cartons of blister per minute.

The line is composed of:

- Marchesini MB421: is an automatic Thermoformer to produce blisters in PVC/ALU (or different materials on demand).

The machine fills product into cavities, seals them with lidding material and discharges the packaged Blisters with your product; - Marchesini BA100: is an horizontal intermittent-motion cartoner for blister, specifically designed to address the main cartoning applications for medium production rates.

Marchesini MB421

Main Features

The machine is divided into five sections, defined with particular attention to material and product.

- Reel compartment holding the forming material as well as the splicing table;

- Preheating and forming section;

- Galenic section, which encloses the filling station, where product runs on the open web and the lidding material reel;

- Sealing, perforating, coding, and punching section;

- Housing for drive and operating mechanisms and swiveling electric cabinet.

The Thermoformer works horizontally with forming, coding and cutting in intermittent motion, product feeding and sealing in continuous motion.

The film unwinds from the reel and pincers achieve the transport to the forming station.

In the machine design, cGMP norms have been respected and the machine is delivered with the CE mark. The working area is a balcony type layout. A vertical stainless steel panel divides the mechanical machine section, on the rear side, from the working area on the front (operator) side.

All parts below the working area, up to the cutting unit, are designed with uniform and inclined surfaces to convey possible residues to the floor. The section where the formed web flows, up to the sealing unit has no area where dust or product residues could deposit and cleaning is easy.

Machine maintenance is reduced to the minimum. Parts tear and wear is reduced too and there is no mechanical stress thus leading to a major efficiency together with the least downtime. Working stations have no dust or product accumulation and allow easy cleaning.

At a normal machine stop, the machine always holds in a position with preheating and sealing plates in open position to avoid film deformations.

Safety Guards

- Machine Safety protection with electric interlocks to emergency stop the machine in case a door is open;

- Methacrylate panels allow the maximum transparency for inspection and cleaning and full protection for the operator, film and products;

- Easy access resulting in better working conditions and better safety.

Reel Compartment

Independent compartment which can hold only one of the following reel arrangements:

- Two forming reels o.d. 400 mm (15.5″);

- One Jumbo reel o.d. 600 mm (23.25″).

The selection must be made at order placement. Once the machine is equipped with one of the a.m. reel arrangements, it is possible to switch to another layout.

A panel from the front side divides the compartment placed on the machine rear side.

- Clean reels as they are in a protected area enclosed by doors;

- Benefits: Shorter down time due to the reel loading; Less material around the machine resulting in better ergonomics for operators; Protection from static dust and environmental conditions;

- The machine stops automatically when reaching each reel end;

- Manual splicing table for forming film. Splicing achieved with thermoformable adhesive tape. Splice locking safety;

- During the splicing operation the film remains locked on the plate. The safety does not allow a machine start, after splicing, until the safety is cleared.

Preheating & Forming

- Preheating and Forming area placed on the rear side to reduce the overall dimensions in protected environment. Heat and noise do not affect the operator;

- The preheating unit is composed of two plates, which, in intermittent motion, preheat the plastic film. In case of a machine stop, the two plates open;

- The forming is made with pre-punches for the 90% plus compressed air and is carried out in order to use both pre-punches and compressed air in case of PVC+Aluminium or PP+Aluminium blisters, and punch plus matrix die in case of ALU+ALU blisters;

- The machine is equipped with air filter at 5 micron. The station works in intermittent motion. Uniformity of film thickness around the forming die assures best sealing;

- Micrometrical positioning adjustment of the preheating plates to the forming die;

- Even stretching cavities, resulting in a better barrier to the outside agents;

- The molding plate can easily be changed, without tools, having one mounting position only;

- This station has the capability to use aluminum & aluminum by cold forming;

- Film transport with pincers.

Feeding

- Product pre-feeder with lid mounted fix on external column, with a 35 liters product capacity. The feeder includes a vibrating riddle to transfer the product to the chutes, which load it into the cavities;

- Support plate for formed web in anodized aluminum, covered with stainless steel AISI 304;

- At the product loading station, the formed web travels in continuous motion. Adding to this feature the possibility to extend the loading plate allows for maximum flexibility and efficiency in product loading;

- It allows the use of fixed feeders, high speeds and easy feeding;

- Feeding safety to stop the machine in phase, when a product protrudes the cavity, or, if a product lies on the bed outside a cavity.

Sealing

- The platen Type sealing, in intermittent motion, makes a horizontal sliding movement following the web, which travels in continuous motion;

- Blister sealing achieved by specially treated plates, where dots permeate. This combines the three elements of a good seal: time, temperature, and pressure for Blister stability;

- The sealed web is cooled between plates. In case of a machine stop, the upper sealing plate opens automatically to avoid damage to the product;

- The system avoids improper rejects due to closure of the plates after stops, even with Polypropylene.

Perforating, Coding and Cutting

- Enclosed area for sealing, perforating, coding, and cutting;

- Operations for perforating and coding made on the same station;

- The cutting station is independent;

- Punching and coding tools work at a multiple speed of the forming and sealing stations;

- Station for Blister cold embosses coding is available as an option;

- Blister perforation station is available as an option;

- New technologies allow working with zero waste on the stroke dimension gaining sensible savings on material. The scrap automatically guillotined during the punching cycle;

- The unit is available just with discharging conveyor in line;

- Transport to cutting station with pincers.

Blister Discharge

- Blister discharge is carried out through a mechanic system from the punching device up to discharging conveyor;

- Blister discharge conveyor placed in fix position on the machine’s front side, including Blister rejects feature. Blisters reject station for incomplete or empty Blisters into dedicated bin at discharge. Blisters reject station, in case of a Cartoner stop, placed on the connecting conveyor;

- As option it is possible to fit also the conveyor belt in line.

Size Changeover

Tool-free change of parts. Repetitive size changeover without adjustments and tools within a minimum time frame on following groups: Forming – Loading plate and feeding – Sealing, Perforation station – Pulling drum and punching Parts will only mount in correct position.

- Digital readout for adjustments;

- Changeover of variable parameters from the display.

Marchesini BA100

The machine is sold with a new certification CE, complies with current safety standards, accompanied by all the dedicated manuals and customized format change cards.

The machine is equipped with a bucket feeding chain into which, by means of dedicated feeders, are placed the products to be cartoned. Operation is completely automatic. One sensor checks for the presence of the product in the bucket and calls the correspondent carton and leaflet (if necessary), enabling the sensors of correct retrieval.

Carton erection is carried out by the traditional blade opening system, which guaranties optimal operation with the widest range of cartons and cardboard quality. Changeover is simple and fast, assisted by millimetric scales.

The Siemens operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages. The speed is set from the control panel and allows for adjustment to the optimal production speed.

The construction is completely mechanical for minimum maintenance, assisted by an ample accessibility to all the parts.

Standard control and safety devices

- Minimum carton and leaflet detectors;

- Leaflet presence checking device;

- Control of correct carton erection;

- Pusher’s safety device;

- Mechanical overload on the main motor;

- Operator’s interface;

- Safety guards according to CE standards, with SCHMERSAL micro switches.

Units

- Automatic feeders for blister;

- Prefolded leaflet inserter;

- Coders;

- Faulty or incomplete carton ejecting device.

Technical data

Forming draw depth MB421

- Max. 12 mm

Max. Punching cycles MB421

- 220 per Minute

Maximum mechanical speed MB421

- up to 60 Cycles/Minute max

- The output always depends on product feeding possibilities, characteristics of the product as well as the Blister configuration, type of Forming and Lid material, automatic product feeders used and on the types of mounted additional accessories

Formats range BA100

- A: Min 20 mm - Max 110 mm

- B: Min 12 mm - Max 55 mm

- H: Min 55 mm - Max 170 mm

Maximum mechanical speed BA100

- up to 80 cartons/Minute

- The production speed is always dependent on the possibility of feeding and characteristics of the product as well as on the configuration of the product, as well as on the accessories added to the standard machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]