BL400VTE-TT

BL400VTE-TT Automatic labeller for self adhesive vignette

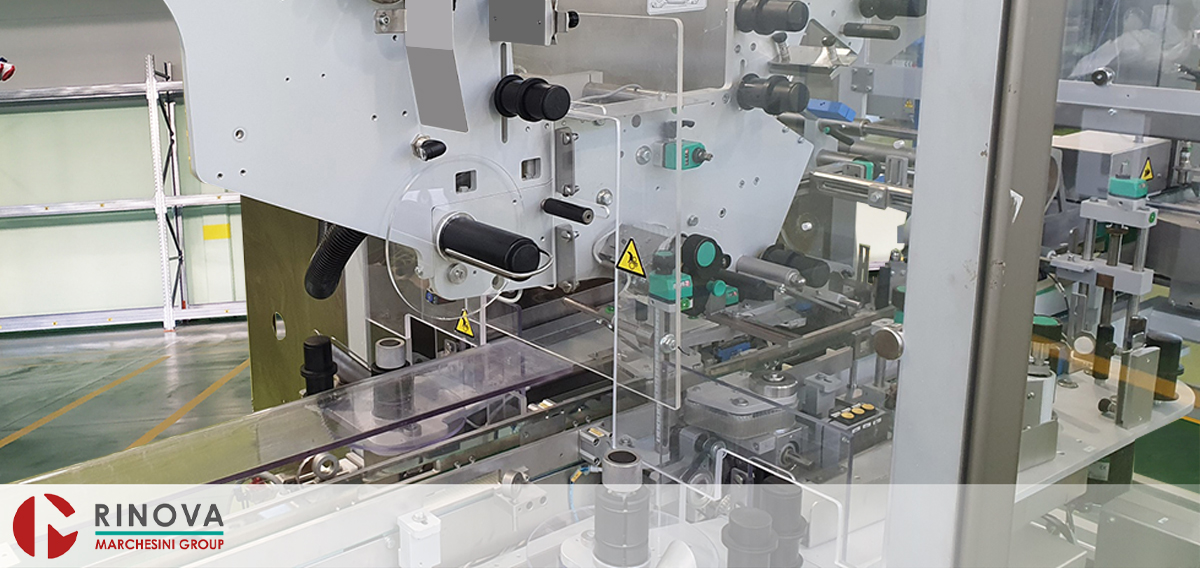

The Marchesini Neri BL400VTE-TT is a continuous motion machine with balcony type, built in steel complying with GMP regulations. Supporting frame and panelling in stainless steel AISI304. Suitable to apply at high production speeds one(1) self-adhesive VIGNETTE on the upper carton face and TWO self-adhesive TAMPER-EVIDENT SEALS on the closure points of formed cartons straight or reverse tuck-in flaps. Conveyance system by toothed belt; unit operating in line with other machines.

Machine suitable for the installation of:

- ink jet or Laser printing system on the upper face and/or on both sides of cartons for printing of readable data as well as corresponding 2D code (Datamatrix);

- relevant camera controls.

Standard Equipment

- Twin horizontal flat conveyor belts, allowing carton accumulation at in-feed;

- Minimum load control at machine infeed with automatic start;

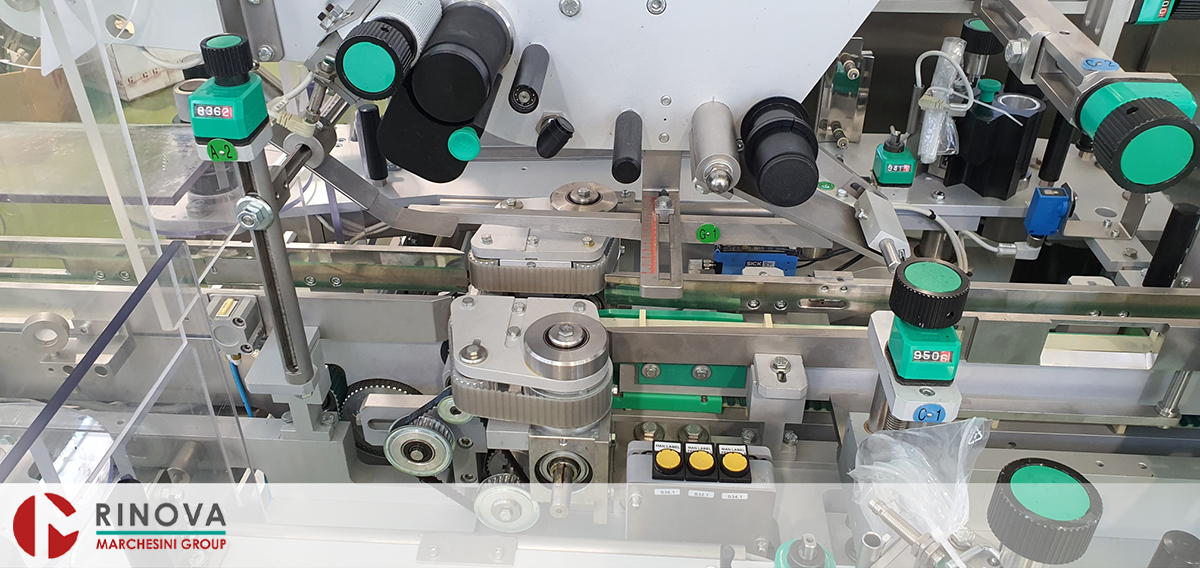

- Timing and distancing device (patented), servo driven, to dispense the cartons onto main toothed conveyor;

- Twin horizontal conveyor toothed belts with adjustable width in order to handle different carton sizes;

- Positive conveyance system. Cartons are kept in pitch, pushed by the vertical cleated belt;

- Continuous mode speed adjustment;

- Automatic working speed synchronization of motors;

- Top belt to hold the seal during placement over the edges;

- Control of pulling motion, of label carrier web;

- End of reel control with machine stop;

- Missing label control on reel;

- Vertical and horizontal adjustment of the TE-SEAL and VIGNETTE position;

- VIGNETTE smoothing system with brushes or rubber rollers;

- TE-SEALS smoothing system with folding devices;

- Folders for straight or reverse tuck-in cartons;

- TE-SEALS and VIGNETTE carrier web rewinding units;

- Regulation of overprint zone on VIGNETTE;

- Maximum load control at the out feed with automatic start,

- Dispensed labels counter;

- All reel holder’s operator side;

- Extracted reel control with alarm;

- Carton reject at discharge and collation in bin on operator side;

- Control rejection bin in position with alarm;

- Tamper Evident internal seals extractable reel, allowing for an easy change.

Machine complete with:

- Power at 400 Volt, 3 phases, 50 Hertz, Ground & Neutral wiring;

- Electric cabinet on board;

- SIEMENS PLC;

- Operator terminal TP700 Touch Screen, 5,7″ color. Seven levels of password;

- Safety Guards in aluminum and Methacrylate. Schmersal type safety switches;

- Machine stop in case a door opens;

- Compressed air control pressure-switch. With machine stop at low-level detection;

- Outfeed carton counter;

- Rejected carton counter;

- Work hour counter;

- The machine has all safeties, required for a safe operation and corresponds to norms;

- Delivered with CE mark;

- Production speed: up to 400 pieces/minute;

- Changeover is made without additional size parts as only some adjustments are sufficient.

Technical data

Carton size

- A: Min 20 mm - Max 120 mm

- B (thickness): Min 15 mm - Max 90 mm

- H: Min 70 mm - Max 250 mm

Label

- A (length): Min 15 mm - Max 80 mm

- B (height): Min 20 mm - Max 60 mm

Seals

- A (length): Min 15 mm - Max 60 mm

- B (height): Min 15 mm - Max 30 mm

Label production speed

- From 0 to 60 meters/minute

Reel diameter

- Max 400 mm

Reel core diameter

- 45 or 75 mm

Production speed

- up to 400 pieces/minute

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]