BA 90 AL

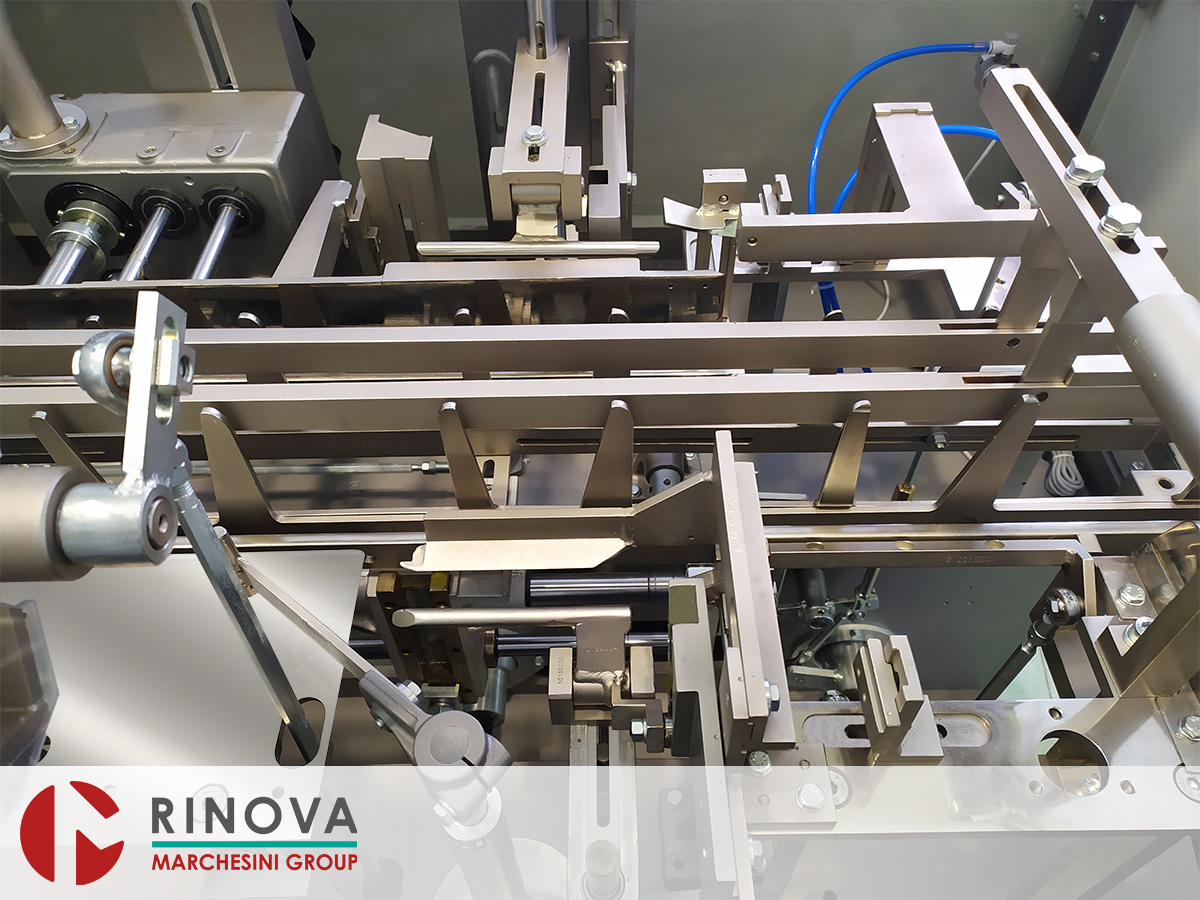

BA 90 AL Intermittent motion cartoner

The Marchesini BA90AL is an automatic, intermittent motion machine and horizontal transport of the carton, suitable to open cartons, to insert the product fed in a bucket chain and to close straight or reverse tuck-in flaps then to discharge the cartons at the outfeed.

Machine complete with:

- Siemens motovariator group;

- The lower machine body, separated from the working area, contains the adjustable speed SBC motor and the BECKER dry type vacuum pump;

- Vertical carton magazine placed at approx. 1400mm (55,12”) from floor level, with minimum load control;

- Mechanical drives are contained inside the frame; carton transport has a fixed and a mobile part adjustable to suit the carton length (“h” dimension);

- Product infeed chain with fixed buckets designed to be connected to various available automatic-feeding units. Infeed and discharge height 820mm +/- 50mm (32,28” +/- 1,96”).

Main Features

- The machine design, result of the long term and proven experience of the manufacturer in this field, has made of “BA 90” a reliable and high-quality machine;

- Solid frame at reduced dimensions, it is realized in compliance with the safety norms and it is delivered with CE mark.

Installed Safeties

- Safety Guard in Methacrylate integrated on the machine frame with safety micro switches on all the opening parts with machine stop in emergency mode and release of the air pressure;

- Electronic torque overload control on the main motor with immediate machine stop;

- Overload safety on product pusher and machine stop. After clearance, a reset is mandatory;

- Machine stop after three consecutive errors.

Technical data

Size range

- A: Min 40 mm (1,57”) - Max 140 mm (5,51”), pitch 200 mm (7,87”)

- B: Min 20 mm (0,79”) - Max 100 mm (3,94”)

- H: Min 90 mm (3,54”) - Max 260 mm (10,24”)

Maximum mechanical speed

- up to 50 cartons/Minute

- The production speed is always dependent on the possibility of feeding and characteristics of the product as well as on the configuration of the product, as well as on the accessories added to the standard machine

Standard voltage

- 400 Volts, 3-phase, Neutral & Ground. Frequency: 50 Hertz

- Electric installations, Panel Layout and wiring according to CE Norms

Electrical system

- The machine complies with international CE standards and is tested according certified Quality Plan

Electric functions

- Commanded by an PLC S7-1500 E HMI TP700 (Siemens)

PC Control Panel complete with:

- Start, stop, reset and emergency push buttons

- Jog connector

- Password protected services access

- Touch screen display to visualize advisory messages to the operator as well as necessary size management selections

- Function and machine status information

- Production data: partial hours counter with reset, total hours counter, good products counter, speed indicator

- Message presentation including services and Help menu

- Two additional foreign languages can be added to Italian language

- Conforming to EMC norms (El. Magnetic Compatibility)

Pneumatics

- SMC

Noise level

- Not exceeding 80 dB(A)

Technical documentation

- Original standard CE Instructions Manual (one hardcopy + one CD Rom) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]