What is the end result of a RINOVA refurbished machine?

- New functionalities not present in the original machine;

- Cost savings compared to the purchase of a new machine with the same features;

- Delivery times of an overhauled faster than a new machine;

- A refurbishment with only original parts;

- New safety devices and software;

- New electrical panel;

- New manufacturer’s warranty;

- New CE Certification;

- After-sales service;

- Customer care.

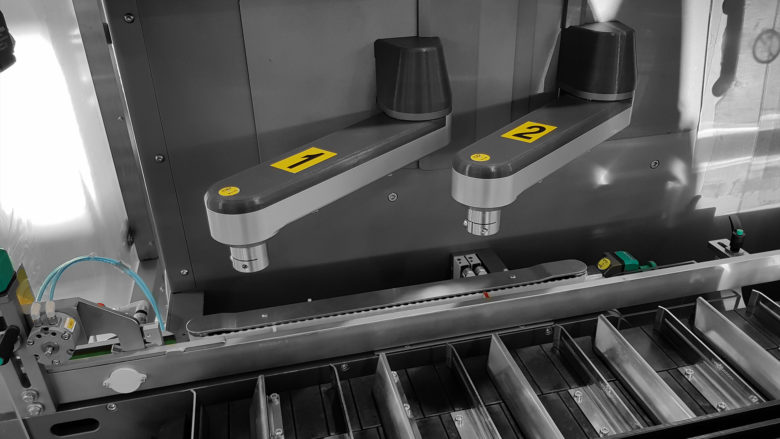

RINOVA can refurbish any second-hand machine from the Marchesini Group with its original parts, even if already owned by the clients.

Find out how to obtain important economic benefits in terms of savings and optimization, request a quote for the purchase of one of our used, reconditioned ones.

Contact us, [email protected], we are waiting to hear from you!