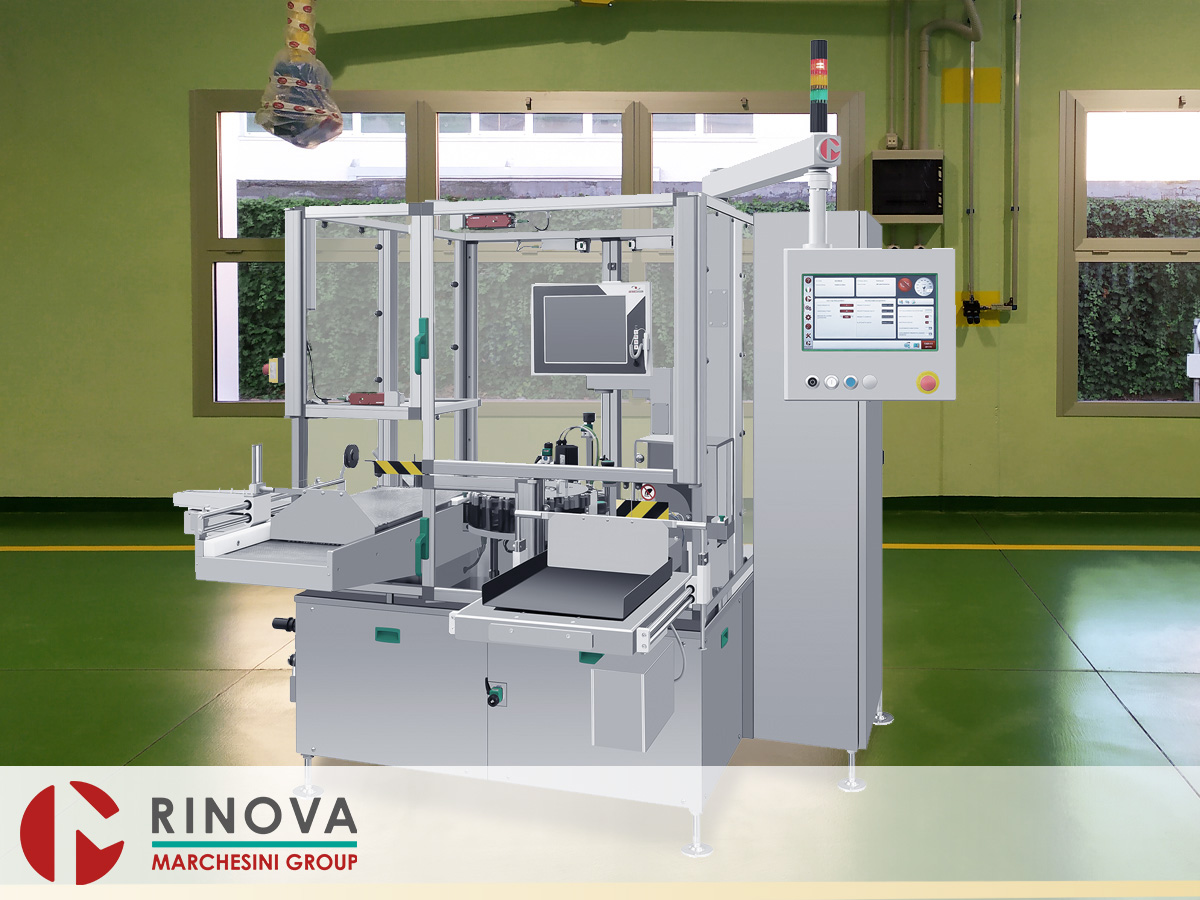

RL-F500

RL-F500 Automatic machine suitable to apply labels

The Marchesini Neri RL-F500 is an automatic machine suitable to apply labels at high production speed on vials, ampoules, cartridges and cylindric containers. Unit operating in line with other machines or as a free-standing unit from tray to tray.

Main Features

- Design, manufacturing and ergonomics, in accordance with GMP norms.

- AISI 304 stainless steel supporting frame and panelling.

- Scroll feeding system, spacing and distributing ampoules or vials, in step on the main transport carousel.

- Container transport roller carousel with adjustable pitch, designed to handle a wide range of sizes.

- Speed adjustment from operator panel.

- One (1) label dispenser.

- Self-learning system of the labels to be handled.

- Provision to store several sizes of labels, with label size recall from HMI (no need to adjust the position of photocells or sensors).

- Stepping feeding of labels, allowing empty spaces on reel.

- Horizontal and vertical adjustment of the labels position by means of hand wheel control complete with mechanical digital indicators.

- Micrometric adjustment of the overprint position on the labels.

- Label smoothing system with a “mousse” rubber belt.

- Automatic reel unwinding unit.

- Backing paper rewinding unit with mechanical clutch.

- Dispensed label counter visible on display.

- Products extraction system from the main transport carousel, by means of an extraction drum with rubber suction cups.

- Scroll for the products transfer from the extraction drum to the machine outfeed.

- Wrong product rejection system positioned in the transfer screw.

- Collation of products on tray.

- Size changeover with no need of specific tools.

- CE marking.

Safeties and Controls

- Safety guards in anodized aluminium frame and methacrylate panels.

- Emergency circuits and protections with safety level “PLd Cat.3”.

- Missing label control on reel.

- End of reel control with machine stop.

- Control for backing paper rewinding unit maximum load, with machine stop.

- Minimum load control at the infeed with machine stop and automatic restart.

- Compressed air control pressure-switch with machine stop at low-level detection.

Included

One (1) ampoules or vials size consisting of: feeding scroll, intermediate guides and discharge screw.

Technical data

Mechanical speed

- 500 pcs/minute

Product diameter

- from 8 to 32 mm (from 0.31” to 1.26”)

Product height

- from 35 to 130 mm (from 1.38” to 5.12”)

Label height

- from 10 to 60 mm (from 0.39” to 2.36”)

Label length

- from 13 to 100 mm (from 0.51” to 3.94”)

Reel diameter

- max. 400 mm (15.75”)

Reel core diameter

- 45 or 75 mm (1.77” or 2.95”)

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]