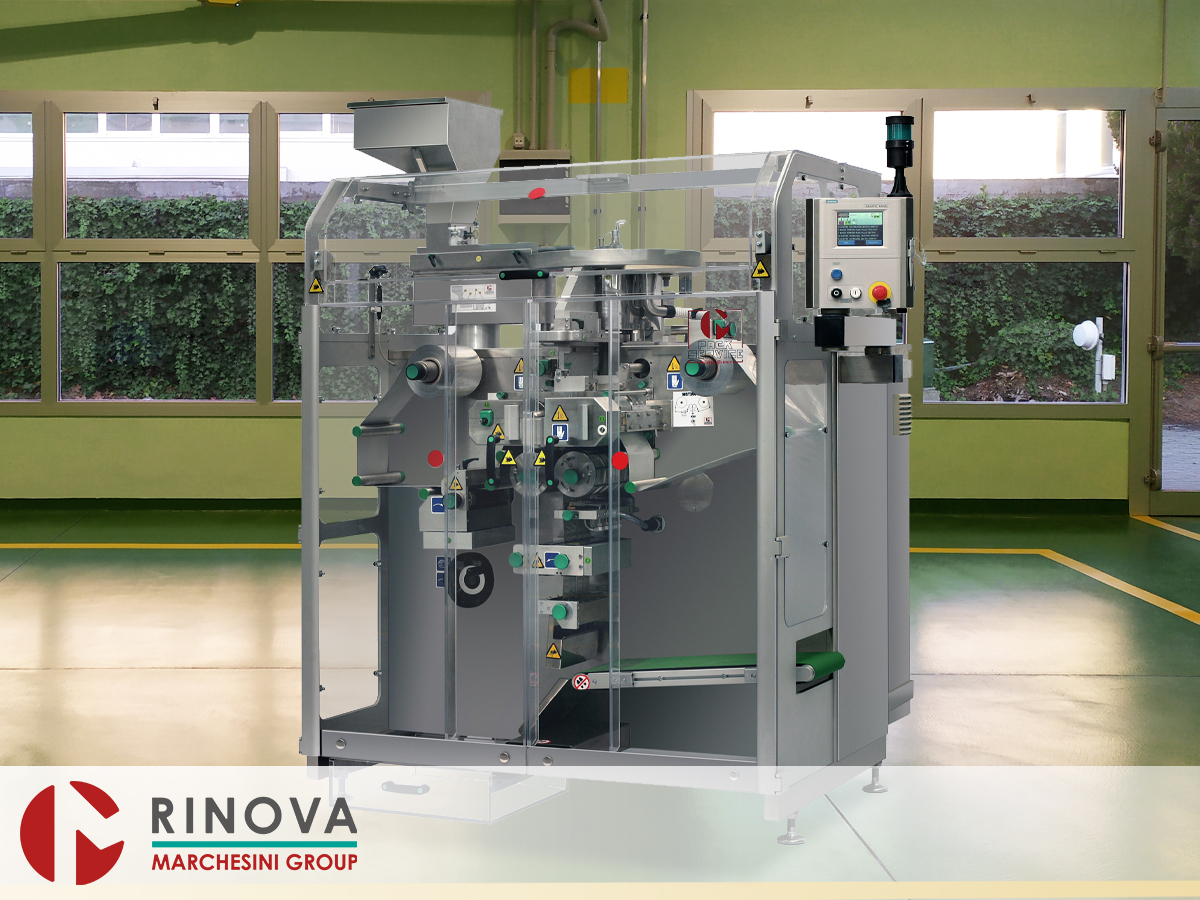

MST 200 mini

MST 200 mini Strip-packer

The Marchesini MST200 mini is an automatic machine for the packing, in heat-sealed strips, of products such as tablets, dragées, capsules, caplets.

Main Features

- Design, manufacturing and ergonomics, in accordance with cGMP norms.

- Machine base frame in AISI 304 stainless steel, with parts in nickel-plated iron and anodized aluminum.

- Balcony design to improve accessibility, maintenance and cleaning operations.

- Working zone on operator side, separated from the rear of the machine.

- Possibility to work different heat-sealable materials (quality and machinability of the heat-sealable materials such as paper, aluminium and multilayers will be evaluated after the execution of internal tests on the preliminary samples).

- Stand-alone operation.

- Quick and easy changeover with limited use of tools, mechanical digital indicators or millimetre scales.

Product Feeding

- Product feeding group, quoted in function of the product to handle.

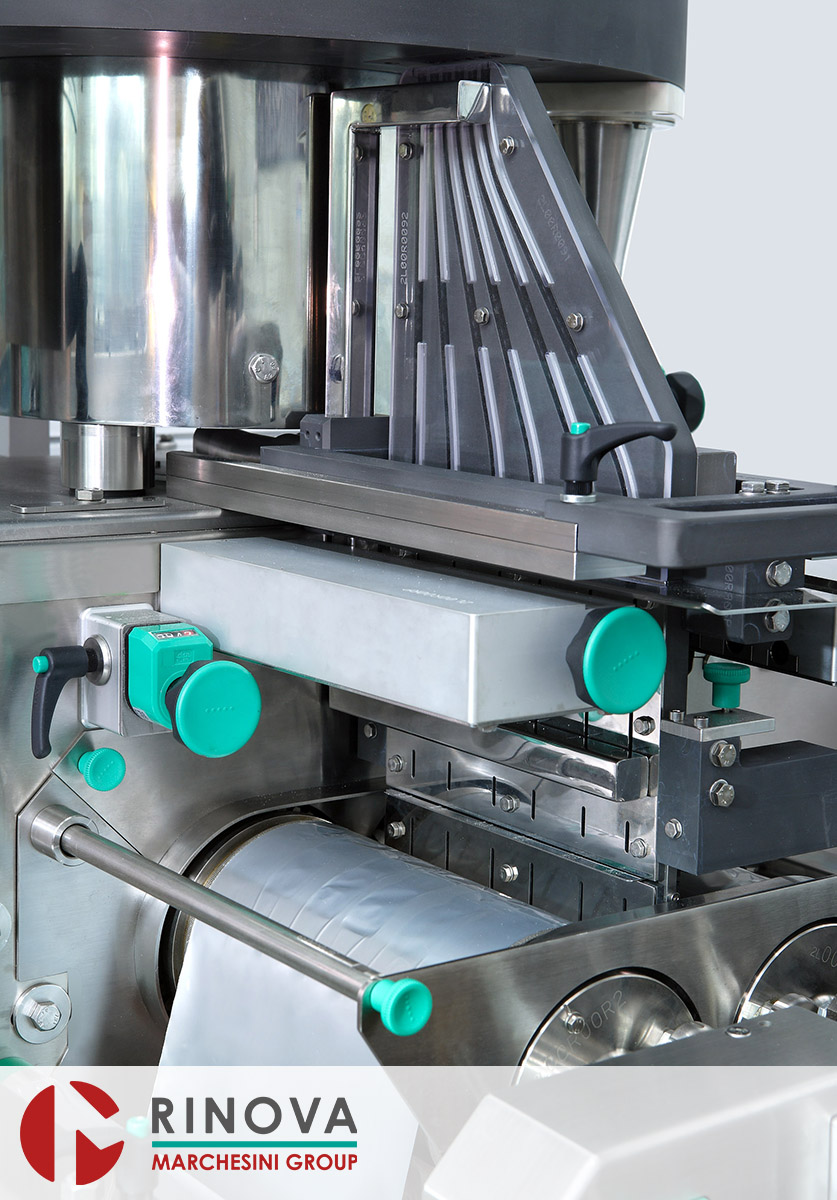

Strip Filling and Sealing

- Film unwinding unit with two (2) reel holders.

- Film pulling group with clutch.

- Film longitudinal cutting group.

- Sealing rollers support group.

- Sealing group composed of two (2) rollers heat-sealing two (2) films, in continuous motion and at high speed.

- Two (2) thermoregulators with visualization of the sealing temperature.

- Rejection of the product left in the sealing rollers in case of machine emergency stop.

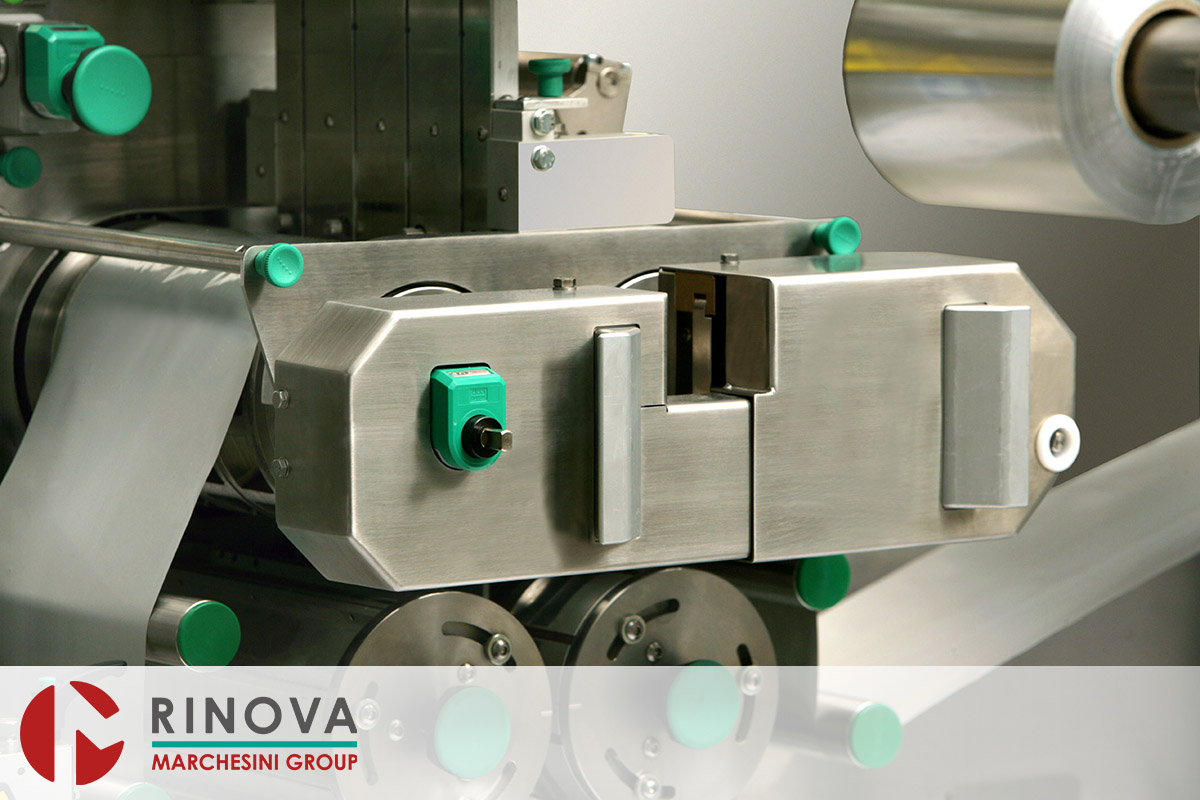

- Transversal cutting group, driven by servo motor, with format size setting of the cuts.

- Rejection group of empty or incomplete strips (rejection is made for all the strips of the same lane).

Controls & Safeties

- Safety guards in methacrylate, integrated in the machine frame.

- Emergency circuits and protections with safety level “PLd Cat.3”.

- Automatic feeding closing and stop in phase of the machine after a number of strokes as set on the display, to avoid product overheating.

- Product presence control inside the strips with rejection of empty or incomplete strips.

- Control of the sealing rollers temperature with signalling on the display and strip rejection.

- End of reel control with pre-alarm and machine stop.

Included

- One (1) sealing format size with four (4) lanes.

Technical data

Mechanical speed

- Mechanical speed:

- The speed always depends on product dimension, number of feeding lanes, sealing material quality, configuration to be executed, as well as installed accessories.

Reel

- Inner diameter: 76 mm (2.99”)

- Outer diameter: Max. 400 mm (15.75”), to be confirmed according to the machine configuration

Width

- Max. 200 mm (7.87”)

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and CE Certificate are supplied with the machine.

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]