BL 200 V-PA-TT

BL 200 V-PA-TT Automatic print&apply labeling machine

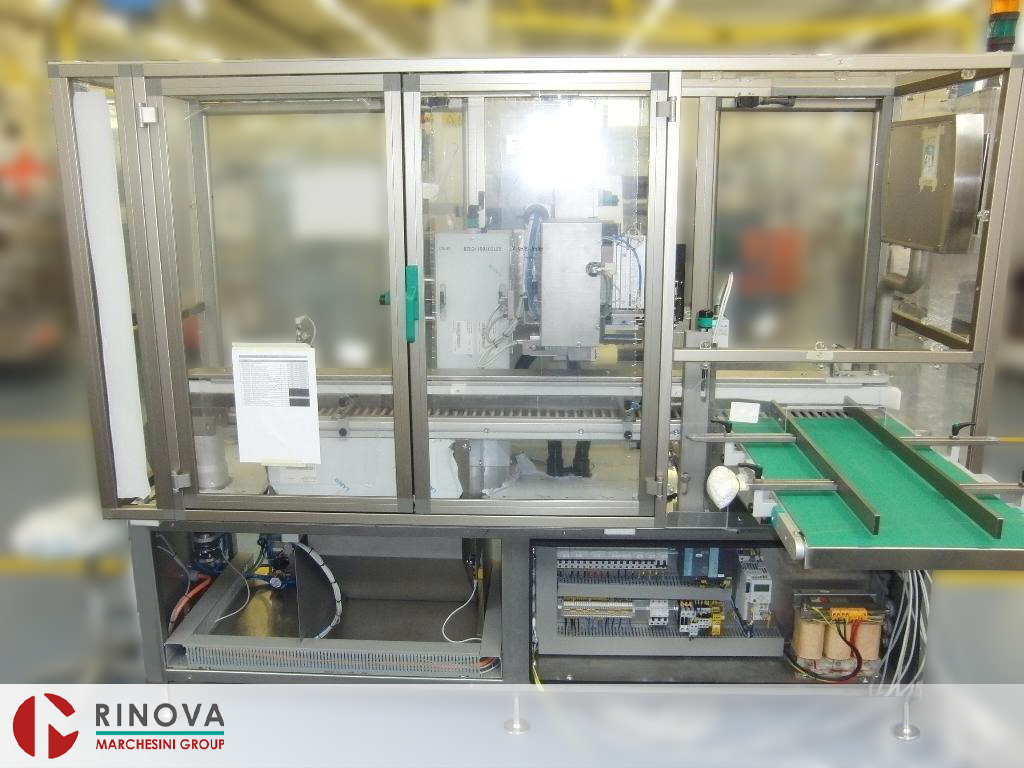

The Marchesini Neri BL200 V-PA TT is an automatic print&apply labeling machine for self-adhesive and Track & Trace labels.

Balcony-type machine with alternating movements, built in steel in accordance with cGMP standards. Support frame and panels in AISI304 stainless steel. Suitable for applying a self-adhesive LABEL on the top side of the bundles, with toothed belt transport and operable in combination with other machines in line.

Machine suitable for installation of:

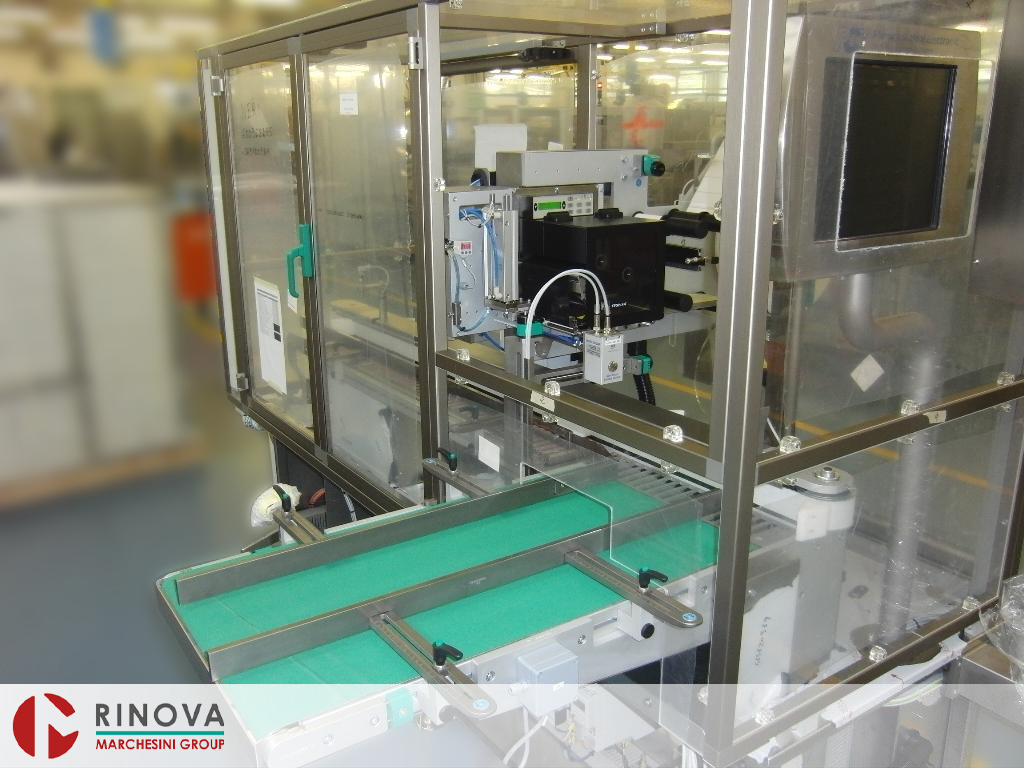

- A Thermal Transfer printing system on the labeling head

- Related camera controls.

Standard Equipment:

- Basic machine with 1 label dispensing head, complete with AISI 304 stainless steel frame and exterior panels in satin stainless steel.

- Infeed belt for connection with the upstream bundler and bundle accumulation, complete with maximum load control.

- Vertical toothed belt conveyor with intermittent movement, for dragging bundles and transporting them through control and labeling stations

- Automatic synchronization of all motors.

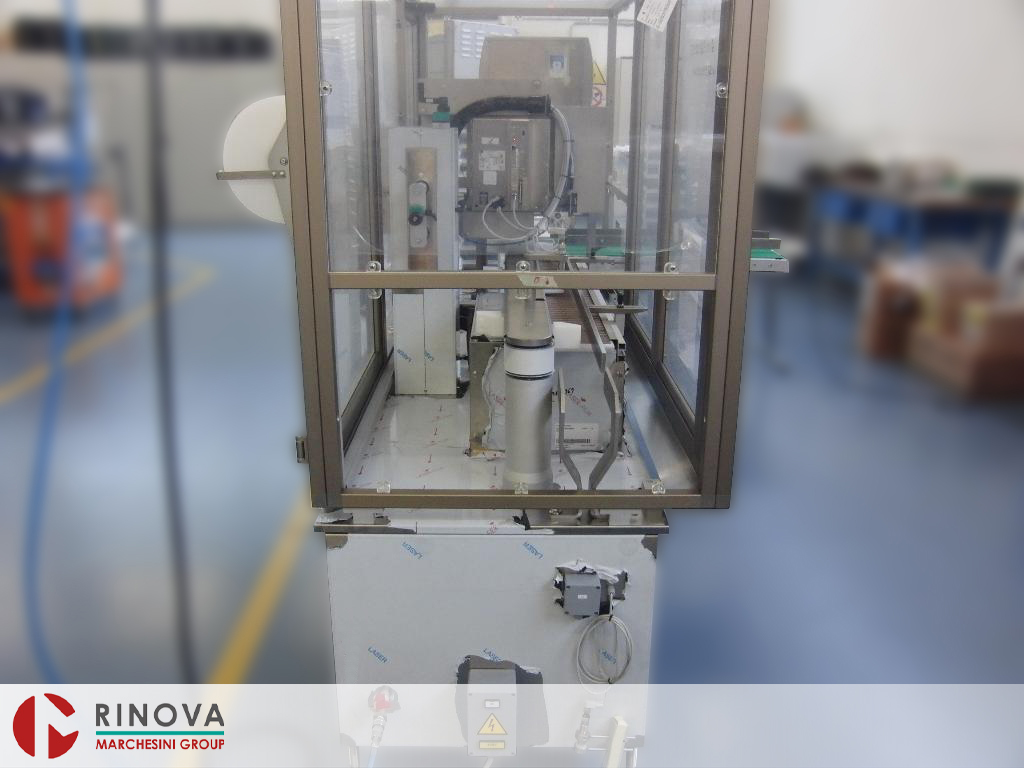

- (1) Vertical head for label distribution and application on the top surface of the bundles, controlled by a servomotor. Print & Apply function, pneumatic applicator with suction plate (format part), label pressing is done with the same applicator.

- Vertical and horizontal adjustment of the label position, using dials equipped with digital indicators.

- Self-learning of labels to be processed, with the ability to store different labels.

- Label size change via keyboard without adjusting the position of photocells or sensors.

- Automatic label unwinders.

- Photocells for reel-end detection, with machine stop.

- Smooth step-by-step advancement of labels, even in case of film gaps.

- Rewinding device for the label backing strip, complete with mechanical clutch.

- Micrometric adjustment of the overprint position on labels.

- Device for checking the maximum output load.

- Reject unit

Complete Machine with:

- Machine control via PC677 SIEMENS Simatic and color Touch Screen operator terminal, with automatic label format change system: self-learning of the labels to be processed, ability to store more than 100 different labels, format change from the keyboard without the need to adjust the position of photocells or sensors.

- Electrical control panel on the machine

- Voltage 400 V, three-phase, N & T, 50 Hertz

- Pressure switch for the compressed air circuit with machine stop in case of pressure drops

- Green signal tower

- Safety devices in accordance with EC regulations

- Safety covers and guards with aluminum frame and methacrylate panels, equipped with Schmersal safety micro switches and machine stop in case of door opening during operation

- A set of format parts for a bundle label size (vacuum applicator)

Technical data

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]