BA 50

BA 50 Intermittent motion cartoning machine for sachets

The Marchesini BA50 is an automatic intermittent motion horizontal cartoning machine for sachets. Suitable to pre‑break and to open three-flap straight or reverse tuck-in cartons, insert product, which has been delivered to the infeed bucket chain, close cartons and discharge

Main Features

- The machine design provides high quality output based on a long term and proven experience in this field. The machine offers the advantage of a minimum space requirement. A heavy-duty structure grants safe performance. In the design, safety norms have been followed and the machine is delivered with the CE mark.

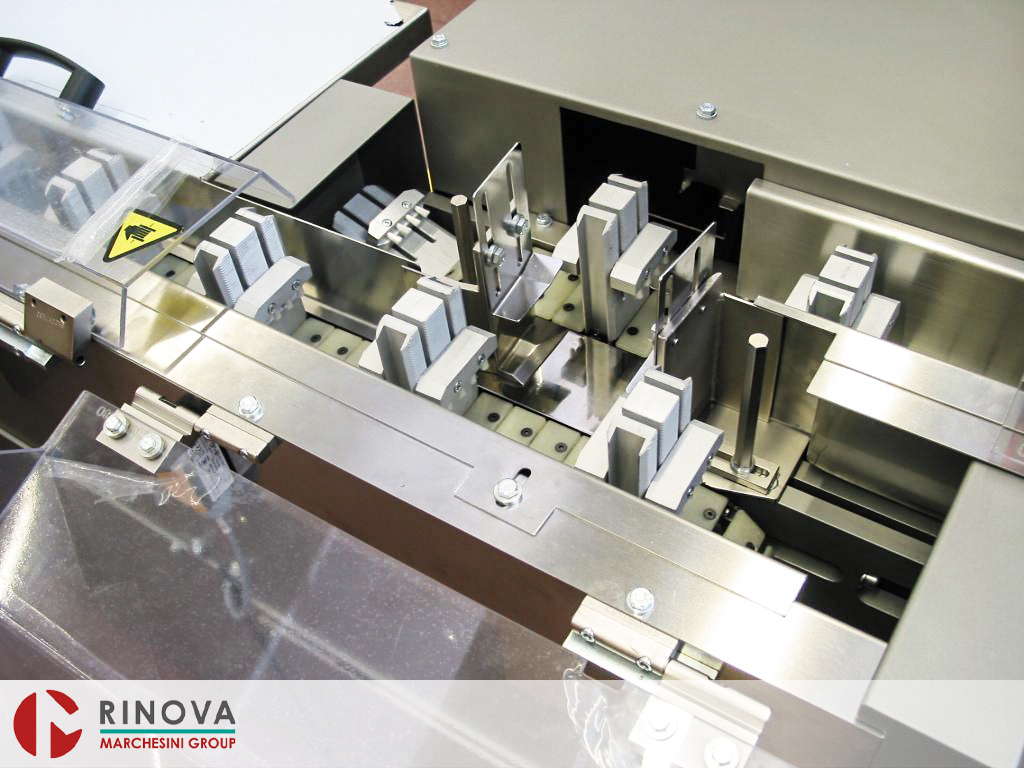

- Supporting structure containing the mechanical drives. Carton transport has a fixed and a mobile part adjustable to suit the carton length (“h” dimension) by a servomotor.

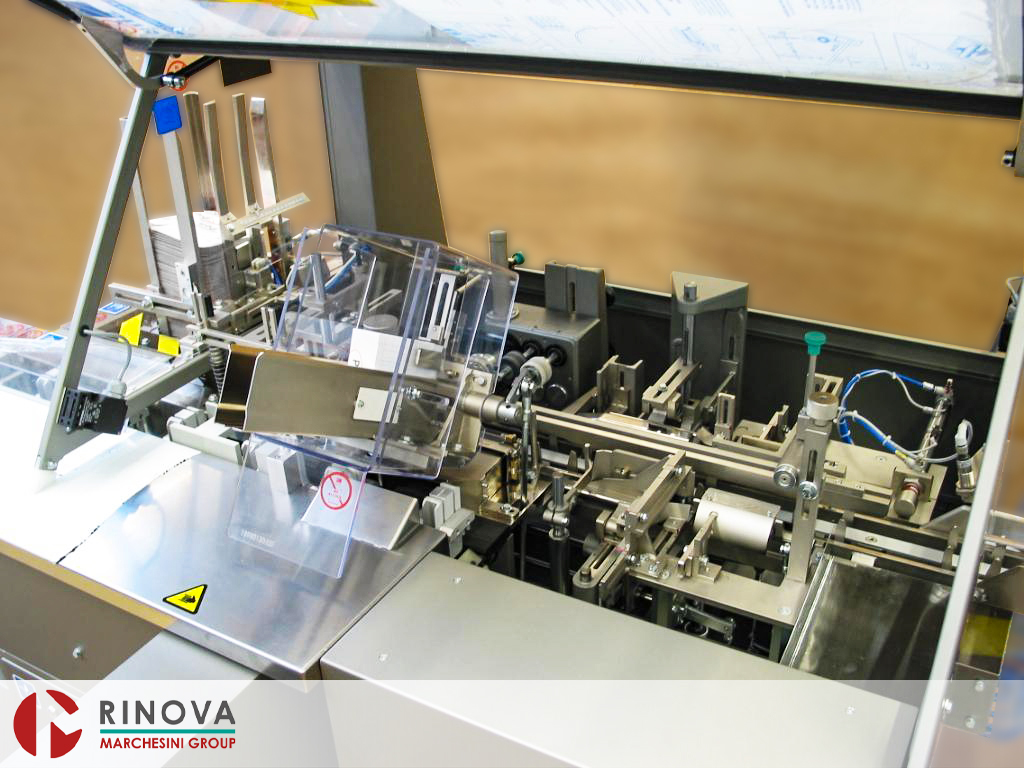

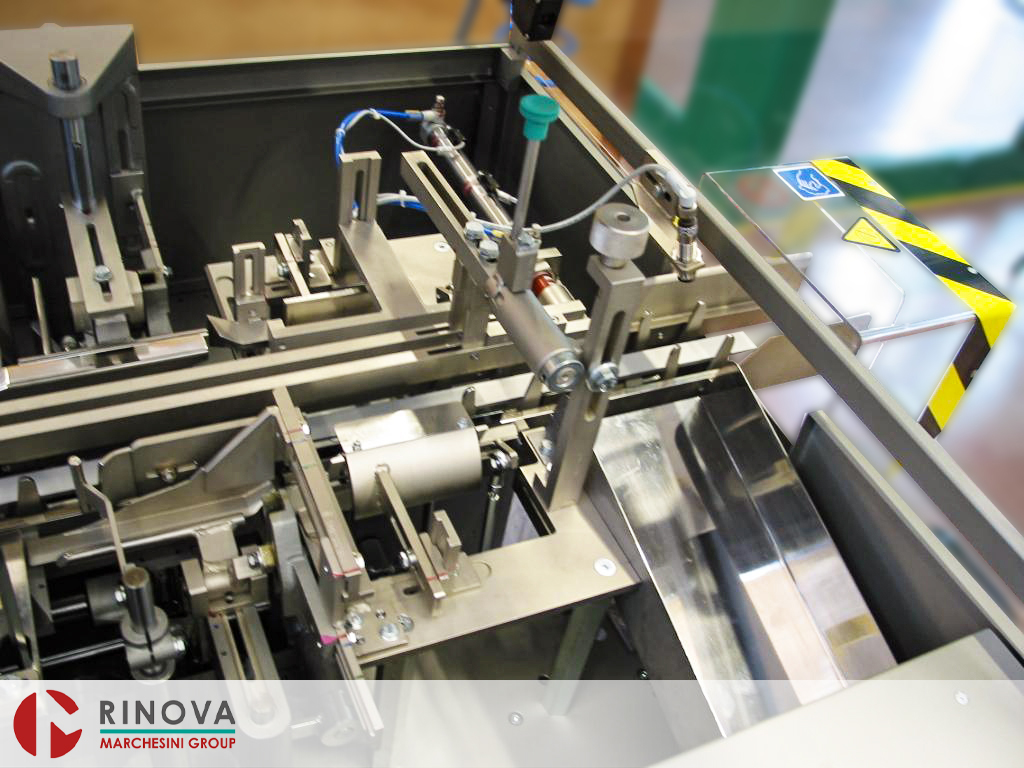

- The lower machine body contains the variable SBC drive and the BECKER dry type vacuum pump and is separated from the working area to allow for easy cleaning. Vacuum distributions achieved by solenoids.

- The leaflet feeding groups, if ordered as option, are enclosed within the safety guard with the loading guides outside.

- A leaflet feeding group, taken from magazine or a GUK open sheet folder can be set up.

Product Feeding

- Product infeed chain with fix buckets designed to be connected to various available automatic-feeding units. Infeed and discharge height 860mm +/- 50mm (33,858” +/- 2”)

Cartoning Section

- Vertical carton magazine, standard length 400mm (15,747”), at approx. 1300mm (51,180”) from floor level, with minimum load control. Magazine guide adjustment with colour points references.

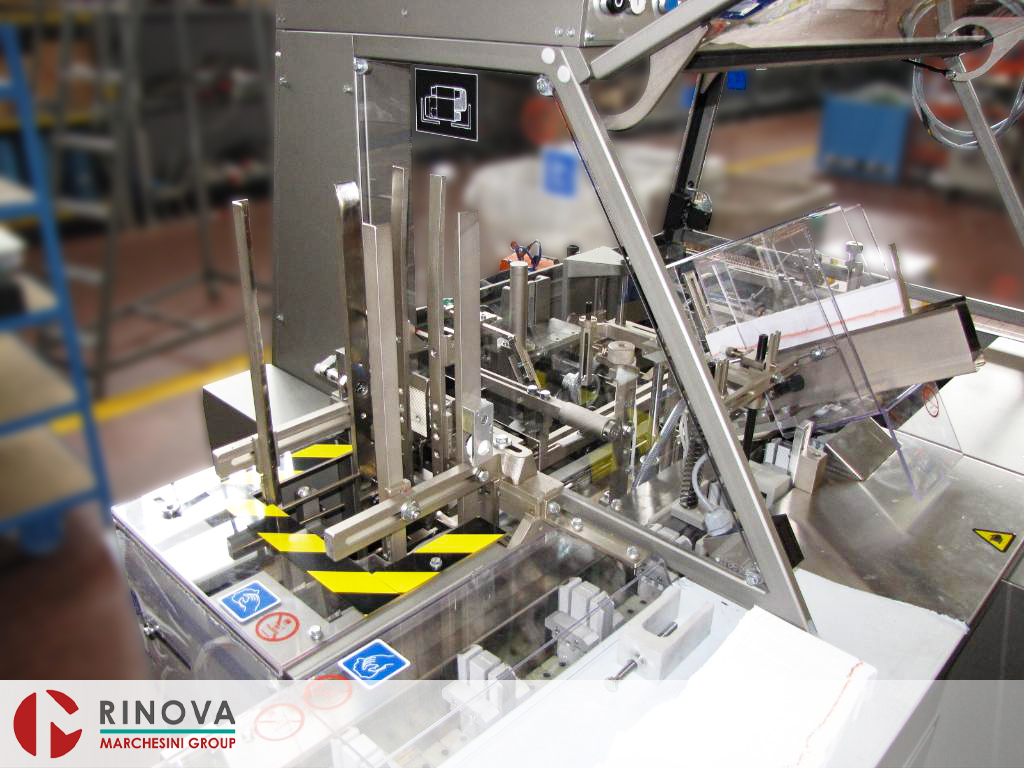

- Only if a product is present the carton is picked-up by an arm with suction cups and transferred to the pre-breaking and opening station with a blade and opening levers. Positive carton pick-up control from magazine.

- After pre-breaking the carton is transported by a rake with alternate movement to the working station maintaining it in square. Sensor checks correct opening and calls for the leaflet (if group is mounted). A further sensor checks for product presence at the station prior to insertion. If product is missing at this point the machine stops to avoid producing an empty carton.

- Servo powered adjustment for change in carton length (“H” dimension).

- Product arriving from the infeed chain is inserted with a pusher placed on operator side. The product is guided into the carton through a moving funnel. The funnel retracts after the pusher is moved out to grant that the product is maintained inside the carton.

- After the closing operation the rake pushes the carton to the discharge guides.

Installed Safeties

- Safety Guard in Methacrylate, (see through) with electric interlocks, safety micro switches on opening positions. Machine stop in emergency mode and release of compressed air. Integrated in the machine frame.

- Overload control on the main motor with mechanical torque limiter and immediate machine stop.

- Overload safety on product pusher and machine stop. After clearance, a reset is mandatory.

- Machine stop after three consecutive errors.

- No product, no carton, no leaflet (if group is mounted).

Machine complete with:

- Fix bucket infeed chain for product.

- Size change indicators with colour points reference

- Machine complete in all parts equipped to handle one size product and carton.

Technical data

Mechanical speed

- up to 55 cartons/Minute

- The output always depends on product feeding possibilities; automatic product feeders used, applied solution for product pusher and on the types of mounted additional accessories

Size Range

- A width: from 40 to 140 mm, pitch 200 mm,

- B height: from 20 to 80 mm

- H length: from 70 to 190 mm

Technical Documentation

- Original standard CE Instructions Manual (one hardcopy + one CD Rom) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]