BL-A420 CW

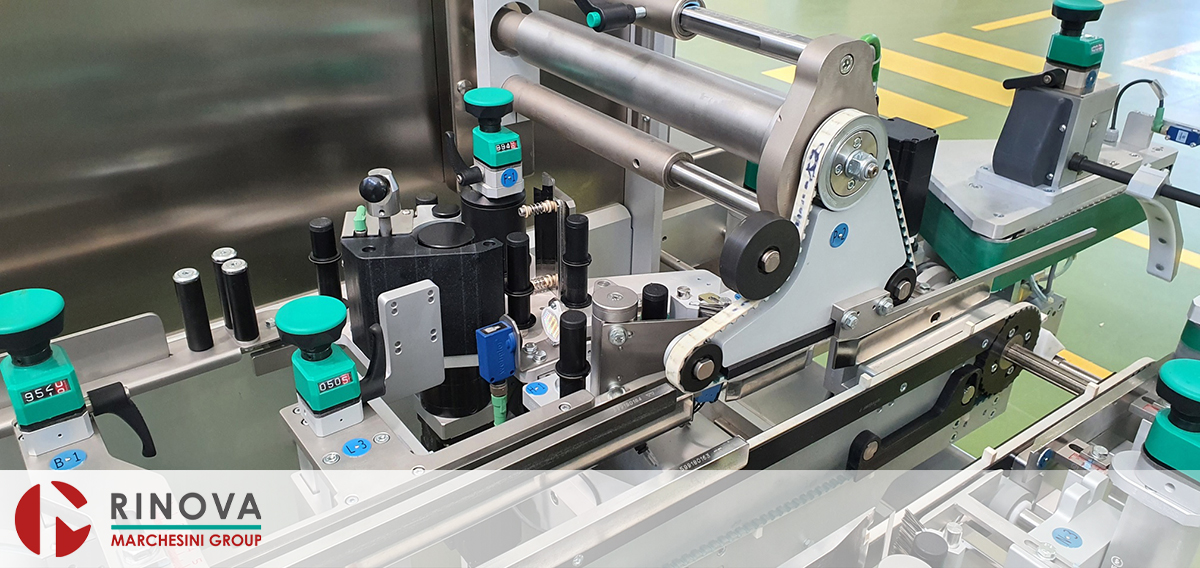

BL-A420 CW Carton labelling machine

The Marchesini Neri BL-A420CW is a continuous motion machine, with integrated Checkweigher for cartons dynamic weighing, suitable to apply (if properly equipped), one (1) self-adhesive VIGNETTE on the upper carton face and two (2) TAMPER-EVIDENT “TE” SEALS on the closure points of formed straight or reverse tuck-in flaps cartons. Unit operating in line with other machines and arranged for TRACK&TRACE applications.

Main Features

- Design, manufacturing and ergonomics, in accordance with cGMP norms.

- Balcony design, AISI 304 stainless steel supporting frame and panelling.

- Twin horizontal conveyor belts, allowing carton accumulation at the infeed.

- Spacing device (patented) transferring the cartons onto the main toothed belts conveyor having adjustable width to handle different carton sizes.

- Integrated checkweigher (dynamic weighing), with automatic reject of the out of range cartons.

- Positive conveyance system with toothed belts to keep the cartons in pitch.

- Speed adjustment from display.

- Top belt to hold the cartons during the application of the TE-Seals.

- Horizontal and vertical adjustment of the Vignette and TE-Seals position.

- Vignettes smoothing system by brushes or rubber rollers.

- TE-Seals smoothing system with folding devices for straight or reverse tuck-in cartons.

- Vignettes and TE-Seals carrier web rewinding units.

- Regulation of overprint zone on Vignette.

- Dispensed labels counter.

- Vignettes reels on operator side.

- Carton reject at discharge with collection inside bin placed on operator side.

- Control of the rejection bin position with alarm.

- TE-Seals extractable reel, for an easy change.

- Guided adjustments for easy and quick size changeover, without additional size parts (machine trials and adjustments for 1 size changeover are included).

- CE marking.

Safeties and Controls

- Safety guards in methacrylate, integrated in the machine frame.

- Emergency circuits and protections with safety level “PLd Cat.3”.

- Minimum load control at machine infeed with stop and automatic restart.

- Control of pulling motion, of label carrier web.

- Broken web detection with immediate machine stop.

- End of reel control with machine stop.

- Control for backing paper rewinding unit maximum load, with machine stop.

- Missing label control on reel.

- Extracted reel control with alarm.

- Reject confirmation.

- Machine stop after three consecutive errors.

- Compressed air control pressure-switch with machine stop at low-level detection.

Not included (quoted separately)

- One (1) “V” labelling head with unwinder.

- Kit of two (2) “TE” labelling heads with double unwinder.

Optional Accessories

- Equipment for Track & Trace applications: Ink jet system or laser printer installed in vertical or horizontal position, for the printing of readable data as well as corresponding 2D code (Datamatrix) on the lateral flaps or on the upper face of the carton; vision system camera for relevant controls.

Technical data

Mechanical speed

- up to 300 pcs/minute, in function of the carton weight. (max. speed = minimum weight) (minimum speed = max. carton weight)

Labels production speed

- from 0 to 60 meters/minute

Weighting Range up to 300 pcs/minute

- from 0 to 750 g

Carton size range

- A (width): from 25 to 105 mm (from 0.98” to 4.13”)

- B (height): from 15 to 90 mm (from 0.59” to 3.54”)

- H (length): from 70 to 160 mm (from 2.75” to 6.30”)

Vignette sizes

- A (length): from 15 to 80 mm (from 0.59” to 3.15”)

- B (height): from 20 to 60 mm (from 0.79” to 2.36”)

TE-Seal sizes

- A (length): from 15 to 60 mm (from 0.59” to 2.36”)

- B (height): from 15 to 30 mm (from 0.59” to 1.18”)

Reel diameter

- Max 400 mm (15.75”)

Reel core diameter

- 45 or 75 mm (1.77” or 2.95”)

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]