MA 260

MA 260 Horizontal cartoning machine for blister

The Marchesini MA260 is a continuous motion, high speed, horizontal cartoning machine, suitable for packing products into three-flaps straight or reverse tuck-in cartons.

Main Features

- Design, manufacturing and ergonomics, in accordance with cGMP norms.

- Versatility and efficiency in a small footprint.

- Balcony design to improve accessibility, maintenance and cleaning operations.

- Working zone on operator side for cartons, products and leaflets transport, separated from the rear of the machine enclosing the mechanics and the main servo motor drive.

- Movements running in oil bath, enclosed in two drive boxes, for the pushers drive and cartons opening, transport and closing.

- “h” quote (length) motorized adjustment of carton size carried out from the operator panel.

- Sloping surfaces to carry any ejected product or carton towards the operator, for the collection in proper bin.

- Size changeover through handwheels, mechanical digital indicators, millimeter scales and/or tuck-in closure carton size without adjustments.

- CE marking.

Product Feeding

- Product bucket infeed belts with simultaneous adjustment of all infeed buckets (related to product width) by handwheel and size reference gauge.

- Belts product transport designed to be connected to different types of automatic and/or robotized product feeding units.

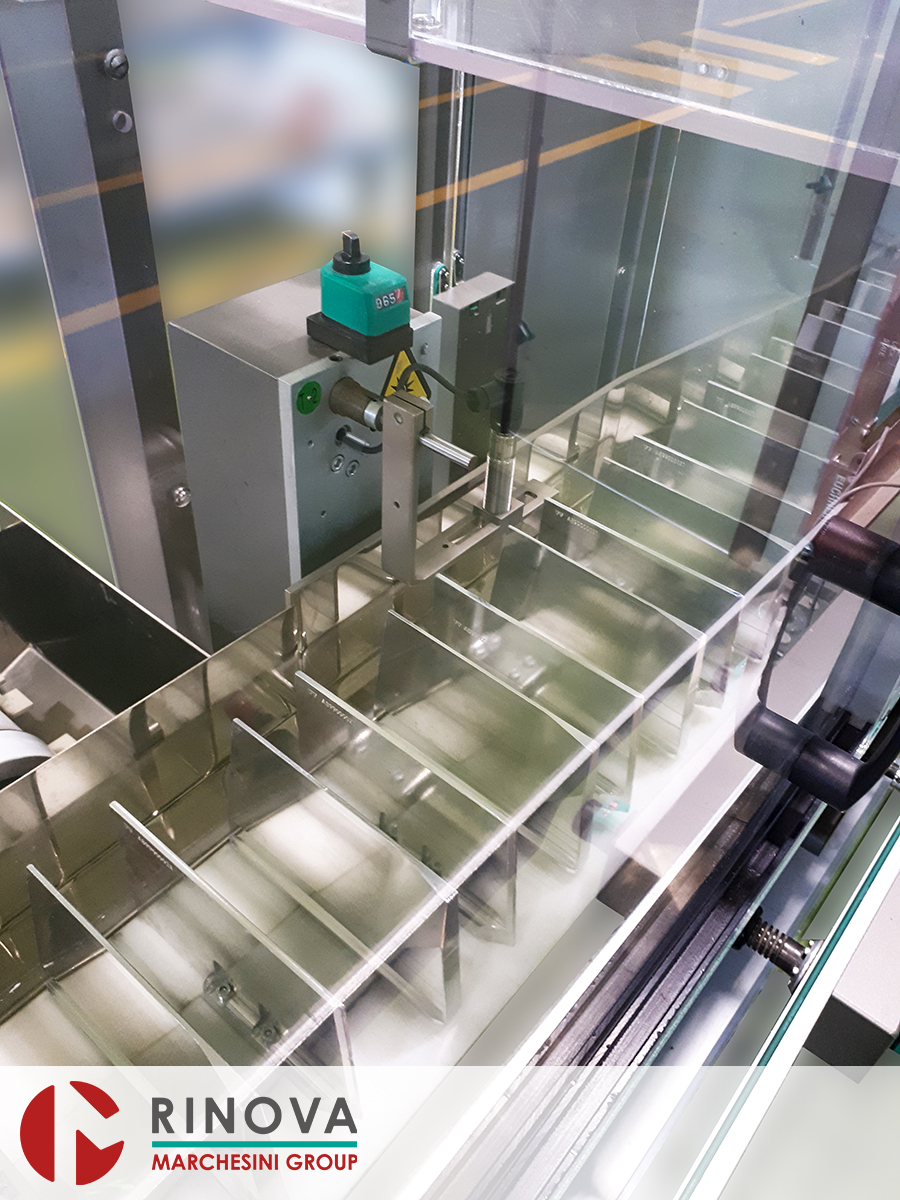

Cartoning Section

- Cartons magazine having a standard length of 1.250 mm (49.21”) placed in a lower position than the product transport belts in order to improve the cartons loading which is made at about 700 mm – 27.56”, equipped with motorized pusher belts and minimum load control.

- Simplified magazine guides and pick up adjustment with millimeter scales and mechanical digital indicators.

- Carton pick up by means of suction cups arms.

- Oscillating suction cups mechanism making the carton opening at 90 degrees.

- Introduction of the carton into the transport lug belts with simultaneous size adjustment from single point of the carton width (“a” quote).

- Product insertion into carton by means of two independent motion pushers, placed opposite the operator side, following the continuous motion of the lug belts.

- Carton closing and transfer to the discharge area, through two lateral accelerating belts.

Safeties and Controls

- Safety guards in methacrylate, integrated in the machine frame.

- Emergency circuits and protections with safety level “PLd Cat.3”.

- Machine stop in emergency mode and release of the air pressure.

- Control of the correct carton opening.

- Control of the leaflet presence before the insertion into carton.

- Overload control on pushers unit during product insertion.

- Minimum loads control on products, cartons and leaflets feeding.

- Cross control product-carton-leaflet; in absence of product, the machine does not pick up neither carton nor leaflet.

- Overload control on the machine motorizations.

- Carton reject control.

- Machine stop after three consecutive errors.

Included

- One (1) carton and product size.

Optional Accessories

- Embossing, inkjet or laser cartons marking.

- Different types of carton closures (hotmelt and/or tuck-in closures).

- Pre-folded leaflets magazine or GUK open/from reel sheets folder, installed within the safety guard and loaded from the outside.

Technical data

Mechanical speed

- up to 260 cartons/minute

- The output depends on product characteristics, feeding groups and installed accessories

Carton Sizes

- A width: from 30 to 90 mm – Pitch: 110 mm

- B height: from 15 to 90 mm

- H length: from 75 to 150 mm

Technical documentation

- Original standard Instructions Manual (one hardcopy + Pendrive) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]